To establish a systematic procedure for the safe and effective Replacement of Pre Fine Semi HEPA and HEPA Filter in order to maintain air quality, ensure optimal equipment performance, and comply with regulatory standards.

SOP for Replacement of Pre Fine Semi HEPA and HEPA Filter

- OBJECTIVE:

- To lay down the procedure for Replacement of Pre Fine Semi HEPA and HEPA Filters.

- SCOPE:

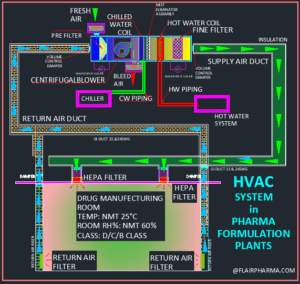

- This SOP is applicable for SOP for Replacement of Pre Fine Semi HEPA and HEPA Filter installed at HVAC (AHU Plenum; Supply Terminals) system, LAF, Pass Box, Sterilization & Depyrogenation Tunnel

- RESPONSIBILITY:

- Technician/ Operator of Engineering Department shall be responsible for proper execution of operation as per SOP for Replacement of Pre Fine Semi HEPA and HEPA Filter.

- Engineering – Head shall be responsible for reviewing the SOP and for ensuring proper execution as per SOP for the Replacement of Pre Fine Semi HEPA and HEPA Filter.

- ACCOUNTABILITY:

- Engineering – Head shall be accountable for proper implementation of the SOP of Replacement of Pre Fine Semi HEPA and HEPA Filter.

- DEFINITIONS:

- Replacement of Pre Fine Semi HEPA and HEPA filter refers to the systematic procedure of removing old or used filters and installing new filters in air filtration systems. These filters are designed to capture particulate matter, allergens, and contaminants from the air, contributing to improved indoor air quality and the efficient operation of various ventilation and air conditioning equipment.

- PROCEDURE for the Replacement of Pre Fine Semi HEPA and HEPA Filter.

- Pre Filter Replacement Procedure for AHU:

- Ensure that no production / testing activity is under process.

- Inform the respective department for filter replacement.

- Ensure that AHU is switch OFF before filter replacement.

- Remove the old filter and clean the plenum of the AHU.

- Check the test certificate of the new filter for their micron rating before installation.

- Check the filter conditions physically.

- Check the gasket and it should be properly paste.

- Frequency of filter replacement for pre filter, if pressure drop or pressure increase or whichever is accursed first, for pressure drop refer SOP/EN/XXXYYY

- Record the filter replacement detail in Format No. SOP/EN/XXXYYY

- SEMI- HEPA Filter Replacement Procedure in AHU Plenum:

- Ensure that no production / testing activity is under process.

- Inform the respective department for filter replacement.

- Remove the old filter and clean the plenum.

- Check the test certificate of the new filter for their micron rating before installation.

- Check the filter condition physically.

- Fix the filter in housing and tight the bolt properly.

- Apply the silicon sealant on flange gasket and nut bolts.

- Check the integrity of the filters as per respective protocol.

- Frequency of changing of HEPA filters is 5 years or if the integrity fails during revalidation or as per pressure drop accursed first, for pressure drop refers SOP/EN/XXXYYY

- Record the filter replacement detail in Format No. SOP/EN/XXXYYY

- HVAC Supply Terminal, DPB and LAF HEPA Filter Replacement Procedure:

- Ensure that no production / testing activity is under process.

- Inform the respective department for filter replacement.

- Remove the filter and clean the plenum.

- Check the test certificate of the new filter for their micron rating before installation.

- Check the filter condition physically.

- Fix the filter in housing and tight the bolt properly.

- Apply the silicon sealant on flange gasket and nut bolt.

- Check the integrity of the filter as per respective protocol and hand over the area / equipment to the department.

- The frequency of changing of HEPA filters is 7 years or if the integrity fails during revalidation.

- Record the filter replacement detail in Format No. SOP/EN/XXXYYY

- Sterilization & Depyrogenation Tunnel HEPA Filter Replacement Procedure:

- Ensure that no production / testing activity is under process.

- Inform the respective department for filter replacement.

- Remove the filter and clean the plenum of the equipment.

- Check the test certificate of the new filter for their micron rating before installation.

- Fix the filter in housing and tight the bolt properly.

- Apply the high temperature silicon sealant on flange gasket and nut bolt.

- Check the integrity of the filter as per respective protocol and hand over the area / equipment to the department.

- The frequency of changing of HEPA filters is 3 years or if the integrity fails during revalidation.

- Record the filter replacement detail in Format No. SOP/EN/XXXYYY

- DPB, LAF, SGC, Tunnel Pre Filter Replacement Procedure:

- Ensure that no production / testing activity is under process.

- Inform the respective department for filter replacement.

- Remove the filter and clean the plenum of the equipment.

- Check the test certificate of the new filter for their micron rating before installation.

- Check the filter condition physically.

- Fix the filter in housing and tight the bolt properly.

- After replacement of filter handover the equipment to the respective department.

- Record the filter replacement detail in Format No. SOP/EN/XXXYYY

- ABBREVIATIONS

- AHU : Air Handling Unit

- HVAC : Heating Ventilation and Air Conditioning

- HEPA : High Efficiency Particulate Air

- DPB : Dynamic Pass Box

- LAF : Laminar Air Flow

- SGC : Sterile Garment Cabinet

- REFERENCES

- Nil

- DISTRIBUTION LIST

- SOP shall be distributed to following departments Quality Assurance, Engineering as per user request.

- ANNEXURES

- Filter Replacement Record: SOP/EN/XXXYYY

Replacement of Pre Fine Semi HEPA and HEPA Filter Logbook and Records

| Sr. No. | Date | Equipment ID | Type of Filter | Filter Sr. No. | Micron Rating | Filter Replacement Due On | Replaced By | Remark |