Tablet compression machines with the right tooling are essential in pharmaceutical plants for the production of solid dosage forms. A critical aspect of these machines is the diverse tooling employed to shape and form tablets. In this article, we will explore the roles played by different types of tooling within tablet compression machines, highlighting their significance in the overall pharmaceutical manufacturing process.

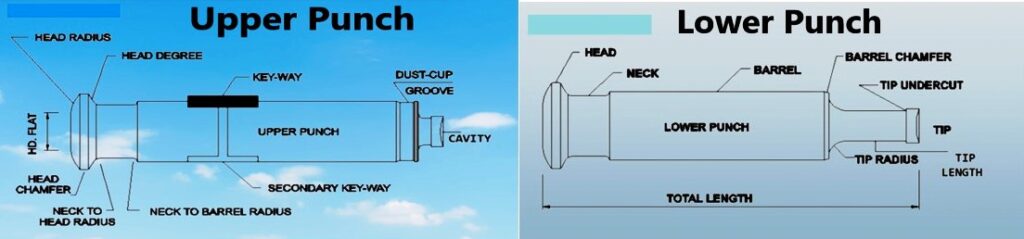

- Punch:

- Punches are a very important part of tablet compression machines. These tooling components shape the tablet by exerting pressure on the formulation, compressing it into a solid form. Punches are responsible for determining the tablet’s size, shape, and surface characteristics. They may feature flat faces (D punches) for plain tablets, or concave faces (B punches) for tablets with curved surfaces or branding.

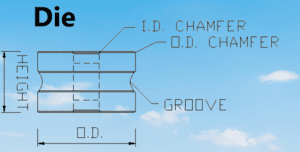

- Dies:

- Dies work in conjunction with punches to form tablets in tablet compression machines. These tooling components provide the cavity or mold into which the formulation is compressed, imparting the tablet’s thickness, hardness, and overall quality. Dies are designed to accommodate specific tablet sizes and shapes, ensuring consistency in the production process. They can have single or multiple cavities, allowing for the simultaneous formation of multiple tablets.

- Feeding Systems:

- Feeding systems in tablet compression machines play a crucial role in ensuring consistent tablet weight and proper distribution of the formulation. These tooling components regulate the flow of the formulation into the compression zone, controlling the amount of material fed into each cavity. The feeding systems maintain uniformity in tablet weight, contributing to the overall quality and efficacy of the final product.

- Cam Tracks:

- Cam tracks are instrumental in regulating the movement of punches and dies within the tablet compression machine. These tuling components guide the vertical and rotational motion of the punches, controlling the compression process. Cam tracks determine the dwell time, ejection, and retraction of punches and dies, facilitating precise tablet formation and ejection from the die cavities.

- Tablet Discharge Chutes:

- Tablet discharge chutes are responsible for guiding the formed tablets out of the tablet compression machine for further processing or collection. These tooling components ensure a smooth and controlled flow of tablets, minimizing the risk of damage or breakage during the discharge process. Tablet discharge chutes play a critical role in maintaining the integrity of the tablets as they exit the machine.

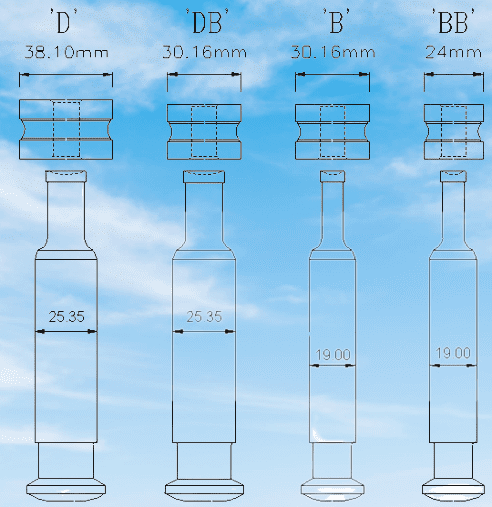

Different Toolings in the Tablet Compression Machine:

| Type of Tooling | Punch Dia. (mm) | Die Dia.(mm) | Punch Length (mm) | Max Size Round/Capsule |

| B | 19 | 30.16 | 133.6 | 16/19 |

| D | 25.4 | 38.1 | 133.6 | 25/25 |

| BB | 19 | 24 | 133.6 | 13/14 |

| DB | 25.4 | 30.16 | 133.6 | 19/19 |

Different Tooling Diagram

The different tooling components in tablet compression machines within pharmaceutical plants each have crucial roles in the tablet production process. Punches shape the tablets, dies provide the cavities for tablet formation, feeding systems ensure consistent weight distribution, cam tracks regulate the motion of punches and dies, and tablet discharge chutes facilitate the smooth ejection of tablets. Understanding the roles of these tooling components is vital for optimizing tablet quality, efficiency, and overall production within pharmaceutical plants.