Cleaning in Place (CIP) is a pivotal process within the realm of pharmaceutical manufacturing, encompassing a sophisticated approach to equipment cleaning. Clean-in-Place (CIP) plays a vital role in maintaining the highest standards of cleanliness and hygiene in pharmaceutical manufacturing. Understanding the important aspects of CIP is crucial for ensuring optimal equipment cleanliness and product quality.

Key elements of the Cleaning In Place CIP in the pharmaceutical industry.

- Equipment-Specific Cleaning Protocols:

- Clean-in-place involves the development and implementation of equipment-specific cleaning protocols. Each piece of equipment has unique characteristics and requirements, necessitating tailored cleaning procedures. By considering factors such as surface material, design complexity, and residue type, Clean-in-place protocols can be optimized for efficient and thorough cleaning.

- Cleaning Agents and Formulations:

- The selection of appropriate cleaning agents and formulations is paramount in Clean-in-place. Cleaning agents must effectively remove various contaminants, including product residues, microorganisms, and other impurities. The compatibility of cleaning agents with equipment materials and their

- ability to achieve the desired level of cleanliness are crucial considerations.

- Process Parameters:

- Precise control of process parameters is essential for successful Clean-in-place. Parameters such as temperature, pressure, flow rates, and contact time are carefully monitored and adjusted to ensure optimal cleaning effectiveness. Deviations in these parameters can compromise the cleaning process and potentially impact product quality.

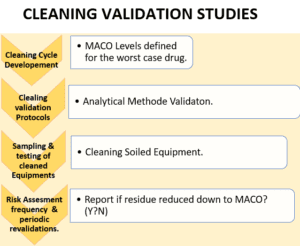

- Validation and Verification: (Cleaning Validation)

- Thorough validation and verification processes are conducted to ensure the efficacy of CIP procedures. This involves testing the cleaning process to confirm that it consistently achieves the desired level of cleanliness. Validation may include microbial testing, visual inspection, and analytical techniques to detect residual products or contaminants.

- Automation and Monitoring Systems:

- Automation plays a significant role in CIP by enhancing efficiency and accuracy. Automated systems can control and monitor the cleaning process, ensuring precise adherence to predefined protocols. Real-time monitoring of critical parameters enables immediate adjustments and helps detect any anomalies or deviations during the cleaning process.

- Risk Assessment and Control:

- A comprehensive risk assessment is conducted to identify potential hazards and implement appropriate control measures in CIP. This includes evaluating the risks associated with cross-contamination, equipment failure, and inadequate cleaning. Risk mitigation strategies such as proper equipment segregation, robust maintenance programs, and effective training protocols are implemented to minimize risks.

- Regulatory Compliance:

- Adherence to regulatory requirements is of utmost importance in the pharmaceutical industry. CIP processes must comply with industry standards and guidelines, including Good Manufacturing Practices (GMP). Regular audits and inspections ensure that CIP procedures are in line with regulatory expectations, safeguarding product quality and patient safety.

Clean-in-Place (CIP) serves as a cornerstone for maintaining cleanliness and hygiene in pharmaceutical manufacturing. By considering these important aspects, pharmaceutical companies can develop robust CIP protocols that meet stringent quality standards, mitigate risks, and ensure the production of safe and effective pharmaceutical products.

Advantages of the Clean-in-Place (CIP)

| Advantages of Clean-in-Place (CIP) in the Pharmaceutical Industry |

|---|

| 1. Ensures thorough cleaning of equipment surfaces, eliminating contaminants effectively. |

| 2. Reduces the risk of cross-contamination between different products or batches. |

| 3. Improves operational efficiency by reducing downtime associated with manual cleaning processes. |

| 4. Enhances product quality by minimizing the presence of residual products and impurities. |

| 5. Provides consistent and reproducible cleaning results, ensuring reliable and predictable outcomes. |

| 6. Supports compliance with regulatory requirements and Good Manufacturing Practices (GMP). |

| 7. Reduces the labor and time required for cleaning, allowing personnel to focus on other critical tasks. |

| 8. Optimizes resource utilization by minimizing water, energy, and cleaning agent consumption. |

| 9. Enables automation and monitoring, ensuring accurate control of process parameters. |

| 10. Facilitates faster equipment changeovers, reducing the risk of contamination during production transitions. |

Steps of the Clean-in-Place (CIP) in the Pharmaceutical Industry.

- Pre-rinse:

- Flushing the equipment with water to remove loose particles and initial contaminants.

- Preparation of cleaning solution:

- Preparing a cleaning solution by diluting or mixing appropriate cleaning agents as per the CIP protocol.

- Circulation:

- Circulating the cleaning solution through the equipment using pumps, ensuring all surfaces come into contact with the solution.

- Contact time: Allowing the cleaning solution to remain in contact with the equipment surfaces for a specified duration to facilitate effective cleaning.

- Rinse:

- Flushing the equipment with water to remove the cleaning solution and dislodged contaminants.

- Final rinse:

- Conducting a final rinse with purified water to ensure the complete removal of any residual cleaning agents or particles.

- Validation:

- Performing validation tests to verify the effectiveness of the CIP process, including microbial testing and visual inspection.

- Post-CIP checks:

- Inspecting the equipment to ensure it meets cleanliness standards and is ready for the next production cycle.

- Documentation:

- Documenting the CIP process, including the cleaning agents used, process parameters, and validation results, for regulatory compliance and record-keeping purposes.

- Equipment changeover:

- If required, prepare the equipment for the next production batch, ensuring proper cleaning and minimizing the risk of cross-contamination.

Applications of Clean-in-Place (CIP) in the Pharmaceutical Industry

| Applications of Clean-in-Place in the Pharmaceutical Industry |

|---|

| 1. Cleaning of mixing vessels and tanks used for the preparation of pharmaceutical formulations. |

| 2. Cleaning of process equipment such as reactors, fermenters, and centrifuges. |

| 3. Cleaning of pipelines, valves, and fittings involved in the transfer of liquids or gases. |

| 4. Cleaning of filling and packaging equipment, including pumps, nozzles, and conveyors. |

| 5. Cleaning of storage vessels and containers for raw materials and finished products. |

| 6. Cleaning of filters and filter housings used for clarification or purification processes. |

| 7. Cleaning of tablet presses, encapsulation machines, and coating equipment in solid dosage manufacturing. |

| 8. Cleaning of cleanrooms, including walls, floors, ceilings, and equipment surfaces. |

| 9. Cleaning of critical utilities such as purified water systems and HVAC systems. |

| 10. Cleaning of sampling equipment used for quality control and analytical testing. |

Frequently Asked Questions:

What is Clean-in-Place (CIP)?

Answer: Clean-in-Place is a method used in the pharmaceutical industry to clean equipment surfaces without disassembling them.

What is Clean-In-Place of CIP system?

Answer: Clean-In-Place (CIP) is a system or method used in various industries, including the pharmaceutical industry, for cleaning equipment and surfaces without the need for disassembly. It is a closed-loop cleaning process that involves the circulation of cleaning solutions through the equipment to remove contaminants and ensure cleanliness. Clean-In-Place systems are designed to automate and streamline the cleaning process, providing efficiency, repeatability, and effectiveness. By using Clean-In-Place, equipment can be cleaned thoroughly, reducing the risk of cross-contamination and ensuring compliance with hygiene and quality standards.

Why is CIP important in the pharmaceutical industry?

Answer: Clean-In-Place ensures proper hygiene, eliminates contaminants, and reduces the risk of cross-contamination, ensuring product quality and patient safety.

Which types of equipment can be cleaned using CIP?

Answer: Clean-In-Place can be used to clean various equipment such as tanks, reactors, pipelines, filling machines, and storage vessels.

What are the key steps involved in the CIP process?

Answer: The key steps in Clean-In-Place include pre-rinse, preparation of cleaning solution, circulation, contact time, rinse, final rinse, validation, post-CIP checks, documentation, and equipment changeover.

What factors are considered when selecting cleaning agents for CIP?

Answer: Factors such as equipment material compatibility, residue type, and desired level of cleanliness are considered when selecting cleaning agents for Clean-In-Place.

How are process parameters controlled during CIP?

Answer: Process parameters such as temperature, pressure, flow rates, and contact time are monitored and adjusted as needed to ensure effective cleaning.

What validation tests are performed after CIP?

Answer: Validation tests may include microbial testing, visual inspection, and analytical techniques to ensure the efficacy of the cleaning process.

How does CIP contribute to operational efficiency?

Answer: Clean-In-Place reduces downtime associated with manual cleaning, allowing personnel to focus on other critical tasks and improving overall productivity.

How does CIP support regulatory compliance?

Answer: Clean-In-Place helps meet regulatory requirements and Good Manufacturing Practices (GMP) by ensuring proper equipment cleaning and documentation.

What are the benefits of using automation in CIP?

Answer: Automation enhances accuracy, control, and monitoring of the cleaning process, leading to consistent and reproducible results.

How does CIP help optimize resource utilization?

Answer: Clean-In-Place minimizes water, energy, and cleaning agent consumption by efficiently cleaning equipment surfaces.

What risks does CIP mitigate in the pharmaceutical industry?

Answer: Clean-In-Place mitigates risks associated with cross-contamination, inadequate cleaning, and equipment failure, ensuring product quality and patient safety.

How often should CIP be performed?

Answer: The frequency of Clean-In-Place depends on the equipment, process, and product being manufactured. It is typically performed between batches or as per a predefined schedule.

Can CIP be customized for different equipment and processes?

Answer: Yes, Clean-In-Place protocols can be tailored to specific equipment and processes to ensure effective and efficient cleaning.

What documentation is required for CIP?

Answer: Documentation for Clean-In-Place includes details of cleaning agents used, process parameters, validation results, and any deviations or corrective actions taken.

What is 3 step CIP?

The term “3-step Clean-In-Place” typically refers to a simplified Clean-In-Place process that involves three main stages of cleaning. Although the specific steps may vary depending on the application and equipment being cleaned, the general concept of a 3-step Clean-In-Place process can be outlined as follows:

Pre-rinse: This initial step involves flushing the equipment with water to remove loose particles, debris, and initial contaminants. The pre-rinse helps prepare the equipment for the subsequent cleaning stages.

Cleaning: In the second step, a cleaning solution or detergent is circulated through the equipment to remove stubborn residues, biofilms, and other contaminants. The cleaning solution is carefully selected based on the type of residues and the equipment being cleaned.

Final rinse: The final rinse is performed after the cleaning stage to flush out any remaining cleaning solution or residual contaminants. Purified water or an appropriate rinsing agent is used to ensure thorough rinsing and complete removal of any cleaning residues.

What is CIP guidelines?

Clean-In-Place guidelines, also known as Clean-In-Place guidelines, are a set of recommendations and best practices that outline the proper procedures for implementing a successful Clean-In-Place process. These guidelines serve as a reference for industries, including the pharmaceutical sector, to ensure effective and efficient cleaning of equipment and surfaces without disassembly.

Clean-In-Place guidelines typically cover various aspects of the cleaning process, including:

Equipment preparation: Guidelines provide instructions on how to prepare equipment for the Clean-In-Place process, such as ensuring proper drainage, removing any removable parts, and securing or protecting sensitive components.

Process Parameters: Process parameters include factors such as temperature, pressure, flow rates, and contact time that are controlled and monitored during the CIP process. Optimizing these parameters ensures efficient cleaning and adherence to cleanliness standards.

Cleaning agents and solutions: Guidelines specify the selection and preparation of appropriate cleaning agents and solutions based on the specific equipment, residues, and cleaning objectives. They may outline recommended concentrations, compatibility, and usage instructions for different cleaning agents.

Control System: The control system consists of instrumentation, automation, and monitoring devices that regulate the CIP process. This system enables precise control of process parameters, monitors performance, and facilitates data recording for analysis and documentation.