A fume hood is a specialized piece of laboratory equipment designed to protect researchers and laboratory personnel from potentially harmful fumes, gases, vapors, or particulate matter that may be generated during experiments or procedures. It serves as a containment system, providing a controlled workspace where these hazardous substances can be safely handled, manipulated, or analyzed. Typically, a fume hood consists of a ventilated enclosure with a transparent front opening, often called a sash or window. This transparent barrier allows researchers to observe and access the interior while providing a level of protection. The enclosure is made of durable materials, such as stainless steel or fiberglass, which are resistant to chemical corrosion and easy to clean.

Typically, a fume hood consists of a ventilated enclosure with a transparent front opening, often called a sash or window. This transparent barrier allows researchers to observe and access the interior while providing a level of protection. The enclosure is made of durable materials, such as stainless steel or fiberglass, which are resistant to chemical corrosion and easy to clean.

The fundamental principle behind a fume hood is to establish a barrier between the laboratory environment and the workspace inside the hood. This is achieved by creating a controlled airflow system. The hood incorporates an exhaust system that removes contaminated air from the workspace and directs it safely away from the laboratory.

By controlling airflow, fume hoods prevent the release of hazardous substances into the laboratory, thus minimizing the risk of exposure to researchers. The airflow is typically achieved through a combination of an adjustable sash, which controls the size of the opening, and fans or blowers that create a negative pressure within the hood. The negative pressure effectively draws air and contaminants into the hood, preventing their dispersion into the laboratory space.

Fume hoods often have additional safety features, such as sensors to monitor airflow velocity, alarms to alert researchers of potential deviations, and filters to remove harmful particulate matter or chemical vapors from the exhaust air before it is released into the environment.

Fume hood working principle

The working principle of a fume hood revolves around the concept of containment and ventilation, aimed at safeguarding laboratory personnel from hazardous substances. Here’s an explanation of the key elements involved in the working principle of a fume hood:

- Enclosure: A fume hood consists of a sturdy enclosure made of materials like stainless steel or fiberglass. This enclosure creates a physical barrier between the laboratory and the workspace inside the fume hood, preventing the escape of harmful fumes, gases, or particles.

- Airflow Control: The fume hood utilizes a combination of airflow control mechanisms to maintain a safe working environment. The primary component for controlling airflow is the adjustable sash, typically made of transparent material. By raising or lowering the sash, researchers can regulate the size of the opening, controlling the intake of air and the release of contaminants.

- Localized Negative Pressure: One of the key principles of a fume hood is the creation of a localized negative pressure zone inside the enclosure. This negative pressure is achieved by employing exhaust systems, such as fans and blowers, which draw air from the laboratory into the fume hood. The negative pressure ensures that any released contaminants are pulled into the hood, minimizing their dispersion into the laboratory space.

- Containment: To enhance containment, fume hoods incorporate adjustable baffles or slats positioned at the back of the hood. These baffles control the airflow within the hood, promoting laminar flow and preventing turbulence. By adjusting the baffles, researchers can optimize the containment of hazardous substances, ensuring that they are effectively captured and directed toward the exhaust system.

- Exhaust System: The captured contaminants are efficiently removed from the fume hood through an exhaust system. This system consists of ductwork, fans, and filters. The fans create a suction effect, pulling the contaminated air through the ductwork and directing it outside the building or through appropriate filtration systems. The exhaust system is designed to maintain proper airflow velocity and prevent the recirculation of contaminated air back into the laboratory.

- Safety Monitoring: Fume hoods often incorporate sensors and monitoring devices to ensure optimal safety. These sensors measure variables such as face velocity, airflow rate, and pressure differentials. If any of these parameters deviate from the predetermined safe ranges, alarms are triggered, alerting researchers to potential risks and prompting necessary corrective actions.

Fume hood for laboratory

Laboratory fume hoods are designed with a singular purpose – to capture and control harmful substances generated during experimental procedures. By employing advanced ventilation principles, these specialized enclosures effectively isolate and exhaust hazardous fumes, ensuring a safe working environment.

How It Works: A Symphony of Components A laboratory fume hood is composed of several key components working in harmony to achieve optimal safety and performance. Let’s explore the crucial elements that bring this symphony to life.

- Enclosure: The primary structure of a fume hood, often made of durable materials such as stainless steel or fiberglass, provides a sealed workspace. This enclosure acts as a physical barrier, preventing the escape of hazardous substances into the laboratory.

- Airflow Control: Central to the fume hood’s functionality is its ability to control airflow. The hood utilizes fans and blowers to create a negative pressure zone, drawing air and contaminants into the enclosure. Adjustable baffles and sashes allow researchers to fine-tune the airflow, optimizing containment and minimizing turbulence.

- Ventilation System: A robust ventilation system complements the fume hood, ensuring the efficient removal of harmful substances. This system comprises exhaust ducts, filters, and fans, which work together to capture and expel contaminated air safely away from the laboratory.

- Monitoring and Safety Features: To maintain optimal performance, laboratory fume hoods incorporate various monitoring and safety features. These include sensors that measure airflow velocity, pressure differentials, and air quality. Alarms and visual indicators are triggered if parameters deviate from predefined thresholds, alerting researchers to potential risks.

- Enhancing Safety Standards: Compliance and Maintenance Ensuring the effectiveness of laboratory fume hoods requires adherence to regulatory standards and proper maintenance practices. Regular inspections, calibrations, and filter replacements are essential to maintain optimal performance and safeguard researchers from potential hazards.

- The Human Touch: Adapting to Diverse Needs While laboratory fume hoods are remarkable engineering feats, the human element remains crucial in their effective utilization. Researchers bring their expertise and understanding of experimental procedures to adapt fume hood usage to diverse scientific needs. Their experience and knowledge supplement the precision of the equipment, creating a dynamic partnership that enhances safety and scientific progress.

Chemical fume hood

A chemical fume hood is a type of fume hood specifically designed for handling and containing hazardous chemical substances in laboratory environments. It provides a controlled workspace where researchers can safely perform chemical experiments and procedures while minimizing their exposure to potentially harmful fumes, vapors, and particles.

Chemical fume hoods function based on the principles of containment and ventilation. The primary objective is to capture and exhaust harmful chemical emissions, preventing them from spreading into the laboratory and safeguarding the well-being of laboratory personnel. Here are some key features and considerations related to chemical fume hoods:

- Enclosure: A chemical fume hood consists of a robust enclosure made of materials resistant to corrosion by chemicals, such as stainless steel or chemical-resistant polymers. This enclosure serves as a physical barrier, preventing the escape of hazardous substances into the laboratory space.

- Airflow Control: Chemical fume hoods employ adjustable sashes or windows to regulate the airflow into the hood. Researchers can raise or lower the sash to control the size of the hood opening, thereby adjusting the intake of air and the release of contaminants. This airflow control helps optimize containment and minimize the potential for chemical exposure.

- Ventilation System: An effective ventilation system is integral to the functionality of a chemical fume hood. It typically includes exhaust fans or blowers that create negative pressure inside the hood, drawing air and chemical contaminants into the hood and away from the laboratory environment. The contaminated air is then safely directed outside the building or passed through appropriate filtration systems.

- Chemical Compatibility: Chemical fume hoods are designed to withstand exposure to various chemicals commonly used in laboratories. The materials used in the construction of the hood, including the lining, surfaces, and sashes, are chosen for their resistance to chemical corrosion and degradation.

- Safety Features: Chemical fume hoods often incorporate safety features such as airflow monitoring devices, alarms, and visual indicators. These help ensure that the hood is functioning properly and that airflow velocities and pressure differentials are within safe operating ranges. Any deviations from these parameters can trigger alerts, prompting researchers to take necessary precautions.

- Regular Maintenance: Proper maintenance of chemical fume hoods is essential to ensure their effectiveness and safety. Regular inspections, calibrations, and filter replacements should be conducted to maintain optimal performance. It is crucial to follow recommended maintenance protocols and adhere to relevant safety standards and guidelines.

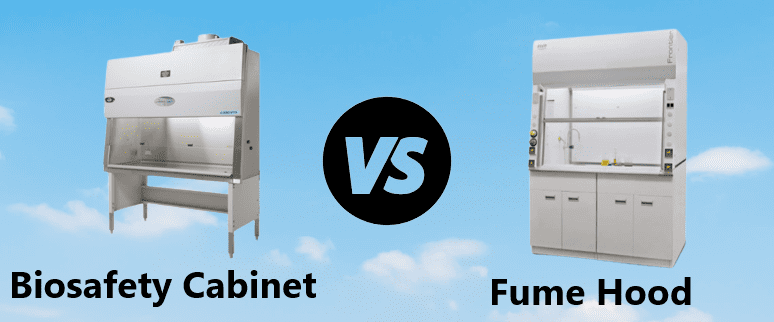

Fume hood vs biosafety cabinet

| Aspect | Fume Hood | Biosafety Cabinet |

|---|---|---|

| Purpose | Captures and controls hazardous fumes, vapors, and particles | Provides both containment and protection for biological agents and contaminants |

| Application | Chemical handling and reactions | Handling infectious materials, microbiological research |

| Airflow Direction | Exhausts air away from the user and the laboratory | Filters and recirculates air within the cabinet |

| Protection Levels | Provides varying levels of protection, depending on the type and design | Offers specific levels of biosafety (e.g., BSL-1, BSL-2, BSL-3, BSL-4) |

| Containment | Provides containment but may not offer absolute containment | Offers a higher level of containment for biological agents and contaminants |

| Airflow Control | Adjustable sash and baffles control airflow | HEPA filters maintain a sterile working environment |

| Purpose-Specific Features | None | UV lights for decontamination, gas sterilization options |

| Applications in Labs | Widely used in chemical laboratories | Commonly found in microbiology and biomedical research labs |

| Personnel Protection | Protects users from chemical exposure and inhalation | Protects users from biological hazards and cross-contamination |

| Environmental Protection | Prevents release of hazardous substances into the laboratory | Prevents release of biological agents into the environment |

| Certification and Compliance | Can meet relevant safety standards and guidelines (e.g., ANSI/ASHRAE 110, EN 14175) | Requires certification based on biosafety levels and guidelines (e.g., CDC, WHO) |

| Equipment and Maintenance Costs | Generally lower cost compared to biosafety cabinets | Higher cost due to specialized features and additional safety measures |

| Usability and Flexibility | Suitable for a wide range of chemical experiments | More specialized for handling biological agents and materials |

| Common Use Cases | Chemical storage, handling volatile substances, heat-generating processes | Microbial culture, cell culture, pathogen research |

Fume hood uses in laboratory

| Use Case | Description |

|---|---|

| Chemical Handling and Reactions | Fume hoods provide a controlled environment for handling and conducting chemical reactions safely. |

| Volatile Substance Storage | Fume hods are utilized to store volatile substances, preventing their release into the laboratory air. |

| Acid Digestion and Solvent Evaporation | Fume hods enable the digestion of samples using acids and facilitate the evaporation of solvents. |

| Heat-Generating Experiments | Experiments that involve heat generation, such as distillation or reflux, can be safely conducted in fume hods. |

| Handling Radioactive Materials | Fume hods offer a barrier for handling and containing radioactive materials, minimizing exposure risks. |

| Biological Experiments and Biosafety | Fume hods with HEPA filters provide a sterile environment for working with biological agents and maintain biosafety protocols. |

| Particle Handling and Dust Containment | Fume hods are used to handle particles and dust, preventing their dispersion in the laboratory. |

| Nanomaterial Handling and Safety | Fume hods aid in the safe handling and containment of nanomaterials, minimizing potential health hazards. |

| Odor Control and Nuisance Fume Removal | Fume hods effectively control and remove unpleasant odors and nuisance fumes, ensuring a comfortable working environment. |

| Quality Control Testing | Fume hods are employed in quality control testing processes, providing a controlled environment for accurate measurements and analysis. |

Frequently Asked Questions

What is the purpose of a fume hood?

Answer: The purpose of a fume hod is to capture and control hazardous fumes, gases, vapors, or particles generated during laboratory experiments or procedures, protecting researchers and maintaining a safe working environment.

How does a fume hood work?

Answer: A fume hod works by creating a barrier between the laboratory environment and the workspace inside the hood. It achieves this through a combination of adjustable airflow control, localized negative pressure, and an exhaust system that safely removes contaminants from the hood.

What types of fume hoods are available?

Answer: There are various types of fume hods, including ducted fume hods (connected to an exhaust system), ductless fume hods (equipped with filtration systems), perchloric acid fume hods (specifically designed for handling perchloric acid), and walk-in fume hods (large hoods for accommodating bulkier equipment).

What are the different levels of fume hood containment?

Answer: The levels of containment for fume hods typically range from low containment (basic capture and exhaust) to high containment (advanced features for handling highly hazardous materials). The specific level depends on the hood’s design, airflow control, and additional safety features.

How should the airflow velocity be measured and maintained in a fume hood?

Answer: Airflow velocity in a fume hood is typically measured using an anemometer. The recommended velocity ranges vary depending on the type of fume hod and the substances being handled. Regular maintenance and calibration are crucial to ensure the airflow velocity remains within safe operating limits.

What are some important safety guidelines for working with a fume hood?

Answer: Safety guidelines include wearing appropriate personal protective equipment (PPE), following standard operating procedures, understanding the chemicals being used, conducting risk assessments, monitoring and maintaining proper airflow, and regularly inspecting the hood for any signs of damage or malfunction.

What is the purpose of the sash in a fume hood?

Answer: The sash in a fume hod acts as a transparent barrier that can be raised or lowered to control the size of the hood opening. It allows researchers to access the workspace while also regulating the intake of air and the release of contaminants.

How often should fume hood filters be replaced?

Answer: The frequency of filter replacement depends on various factors, such as the type of filter, the substances being handled, and the manufacturer’s recommendations. Generally, filters should be replaced regularly to ensure optimal performance and maintain the required level of containment.

Are fume hoods energy-efficient?

Answer: Fume hods can consume a significant amount of energy due to the operation of exhaust systems and fans. However, energy-efficient models are available that incorporate features such as variable airflow control, occupancy sensors, and optimized fan usage to reduce energy consumption.

What certifications or standards should a fume hood meet?

Answer: Fume hods should meet relevant safety standards and certifications, such as ANSI/ASHRAE 110, EN 14175, and SEFA 1, which outline specific testing and performance criteria. Compliance with these standards ensures that the fume hod meets industry-recognized safety requirements and quality benchmarks.