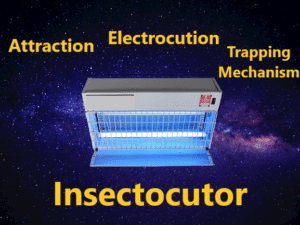

Insect-o-cutor or Insectocutors, also known as electric insect traps or bug zappers, are innovative devices designed to attract and eliminate flying insects. They provide an effective means of controlling pests in various environments, including homes, commercial establishments, and outdoor spaces. The primary goal of insectocutors is to create a pest-free environment by attracting insects to the device and subsequently neutralizing them.

Working principle of Insectocutors

The working principle of insecto-cutors involves several key elements and processes that enable them to attract and eliminate flying insects effectively. Here is a description of the working principle:

- Attraction: Insecto-cutors use various methods to attract flying insects toward the device. The most common method is the utilization of ultraviolet (UV) light sources. Many flying insects are naturally attracted to specific wavelengths of UV light. The emitted UV light acts as a powerful lure, drawing insects toward the vicinity of the insecto-cutor.

- Electrocution: Once attracted to the insecto-cutor, the insects come into contact with an electric grid or mesh. This grid comprises charged wires or metal plates with high-voltage electric current. When the insects touch the grid, they complete an electric circuit, resulting in a sudden electricity discharge. This electric shock electrocutes and eliminates insects. The voltage is typically low enough to eliminate insects but does not pose a significant risk to humans or larger animals.

- Trapping Mechanism: Some insecto-cutors incorporate additional trapping mechanisms to enhance their effectiveness. These mechanisms can include adhesive boards or glue traps positioned near the electric grid. When insects land on these surfaces, they become stuck and unable to escape. This dual approach of electrocution and trapping increases the chances of capturing a wide range of flying pests.

- Collection and Maintenance: Insectocutors usually have a collection tray or drawer beneath the electric grid where the neutralized insects accumulate. This tray can be easily removed for regular cleaning and disposal of captured pests. It is essential to empty the collection tray periodically to prevent the buildup of dead insects and maintain the optimal performance of the device. Additionally, some insecto-cutors may require periodic replacement or cleaning of adhesive boards or UV light bulbs to ensure their effectiveness.

By combining the elements of attraction, electrocution, trapping mechanisms, and collection, insecto-cutors provide an efficient solution for controlling flying insects. They offer a safe and environmentally friendly method to eliminate pests without the use of harmful chemicals or pesticides. The working principle of insect-o-cutors makes them valuable tools in maintaining hygienic environments and creating a more comfortable space free from flying pests.

Components of Insectocutors

| Component | Utilizes UV lamps or bulbs to emit ultraviolet light. Many flying insects are naturally attracted to certain wavelengths of UV light, making it an effective lure for drawing them toward the insectocutor. |

| Electric Grid | A grid or mesh composed of charged wires or metal plates. When insects come into contact with the grid, they complete an electric circuit, resulting in a discharge of electricity that electrocutes them. |

| Ultraviolet (UV) Light Source | Specific models of insect-o-cutors may include safety features such as protective screens or grids around the electric grid to prevent accidental contact by humans or larger animals. These features help minimize the risk of electric shock. |

| Trapping Mechanism | Additional trapping mechanisms such as adhesive boards or glue traps are often positioned near the electric grid. These surfaces capture insects upon contact, preventing their escape and enhancing the effectiveness of the insect-o-cutor. |

| Collection Tray | Located beneath the electric grid, the collection tray collects neutralized insects. It can be easily removed for regular cleaning and disposal of the captured pests. |

| Housing | The outer casing or housing of the insect-o-cutor encloses and protects the internal components. It is usually made of durable materials and may feature a design that allows easy access for maintenance and cleaning. |

| Power Source | Located beneath the electric grid, the collection tray collects neutralized insects. It can be easily removed for regular cleaning and disposal of captured pests. |

| Safety Features | Insect-o-cutors require a power source, commonly utilizing electricity from mains power or batteries. |

| Controls | Some insect-o-cutors are equipped with controls or settings to adjust the intensity of the UV light or activate additional features. These controls allow users to customize the device according to their specific needs and preferences. |

Applications of Insectocutors

| Application | Description |

|---|---|

| Residential | Insect-o-cutors find widespread use in residential settings, such as homes, apartments, and condos. They help control flying insects like mosquitoes, flies, and moths, providing a more comfortable and pest-free living environment. |

| Commercial | Insect-o-cutors are widely employed in commercial establishments, including restaurants, cafes, hotels, and offices. They aid in maintaining hygiene standards by eliminating flying pests, ensuring a pleasant experience for customers and a clean working environment for employees. |

| Food Service Industry | Insect-o-cutors play a crucial role in the food service industry, specifically in kitchens, food processing plants, and storage areas. They help prevent contamination by flying insects, ensuring the safety and integrity of food products throughout the production and distribution processes. |

| Hospitality | Insect-o-cutors are essential in the hospitality industry, encompassing hotels, resorts, and guest accommodations. They help create a welcoming environment by reducing flying pests and enhancing guest satisfaction and comfort. |

| Healthcare Facilities | Insect-o-cutors are utilized in healthcare facilities, including hospitals, clinics, and laboratories. By controlling flying insects, they contribute to maintaining a sterile environment, preventing potential disease transmission, and ensuring patient safety and well-being. |

| Retail Stores | Insect-o-cutors find applications in retail stores, supermarkets, and shopping centers. They help minimize the presence of flying insects, enhancing the shopping experience for customers and preserving the quality of perishable goods, such as fruits, vegetables, and bakery items. |

| Outdoor Spaces | Insect-o-cutors are suitable for outdoor areas like gardens, patios, and camping sites. They help control flying pests during outdoor activities and provide a more enjoyable and pest-free environment for relaxation and social gatherings. |

You may also read about

Frequently Asked Questions

What is the principle of Insectocutor?

Answer: The principle of an Insect-o-cutor is to attract flying insects towards the device using methods like ultraviolet (UV) light sources and then eliminate them through electrocution or trapping mechanisms.

How does an insect killer machine work?

Answer: An insect killer machine, such as an Insecto-cutor, works by attracting flying insects with UV light. Once the insects come close to the device, they either get electrocuted by coming into contact with an electric grid carrying a high-voltage current or get trapped on adhesive boards or glue traps, leading to their elimination.

What are the different types of Insectocutor?

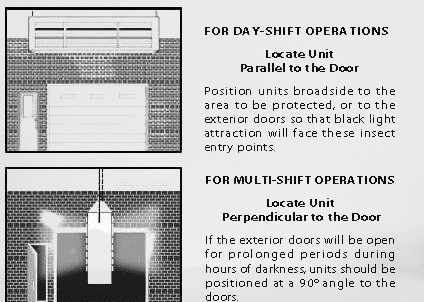

Answer: There are several types of Insect-o-cutors available, including wall-mounted insect-o-cutors, ceiling-mounted insect-o-cutors, portable insect-o-cutors, and outdoor insect-o-cutors. Each type is designed to suit different environments and specific requirements.

How does an electric flytrap work?

Answer: An electric flytrap operates similarly to an Insect-o-cutor. It uses UV light to attract flying insects towards the device. Once the insects approach the flytrap, they either get electrocuted by an electric grid or get trapped on adhesive surfaces, effectively eliminating them.

What is the mechanism of trapping insects in a Venus flytrap?

Answer: The Venus flytrap is a carnivorous plant with specialized leaves that form trap-like structures. When an insect touches the trigger hairs on the leaf surface, it triggers the rapid closure of the leaf. The trapped insect is then slowly digested by enzymes secreted by the plant, providing nutrients for its growth.

Why are bugs attracted to UV light?

Answer: Many insects are naturally attracted to certain wavelengths of light, including UV light. It is believed that insects use light for navigation, food sources, mating, and other behaviors. The specific wavelengths emitted by UV light sources act as a strong attractant for various flying insects.

What is an Insectocutor?

Answer: An Insecto-cutor, also known as an electric insect trap or bug zapper, is a device designed to attract and eliminate flying insects. It typically utilizes UV light to lure insects towards the device and then employs mechanisms like electrocution or trapping to eliminate them.

What are the different types of Insectocutor?

Answer: The different types of Insecto-cutors include wall-mounted insecto-cutors, ceiling-mounted insecto-cutors, portable insecto-cutors, and outdoor insecto-cutors. Each type is designed for specific locations and purposes, catering to different needs and environments.

What is the insect killer device called?

Answer: The insect killer device is commonly referred to as an Insecto-cutor, insect killer machine, or bug zapper. These terms are used interchangeably to describe devices that attract and eliminate flying insects.

How does an Insectocutor attract flying insects?

Answer: An Insecto-cutor attracts flying insects by using ultraviolet (UV) light sources. Many insects are naturally attracted to specific wavelengths of UV light, making it an effective lure.

What is the voltage typically used in an Insectocutor’s electric grid?

Answer: The voltage used in an Insecto-cutor’s electric grid is typically low, ranging from a few hundred to a few thousand volts. This voltage is sufficient to eliminate insects but poses minimal risk to humans.

What is the purpose of the trapping mechanism in an Insectocutor?

Answer: The trapping mechanism in an Insecto-cutor enhances its effectiveness by capturing insects that come in contact with the device. This mechanism can involve adhesive boards or glue traps positioned near the electric grid.

How often should the collection tray of an Insectocutor be cleaned?

Answer: The collection tray of an Insecto-cutor should be cleaned regularly, ideally on a weekly basis or as needed, to remove accumulated dead insects. This helps maintain the device’s performance and hygiene.

Can Insectocutors be used outdoors?

Answer: Yes, there are specific types of Insecto-cutors designed for outdoor use. These devices are typically weather-resistant and suitable for controlling flying insects in gardens, patios, and other outdoor spaces.

Are there safety features in Insectocutors to prevent accidental contact?

Answer: Yes, many Insecto-cutors incorporate safety features such as protective screens or grids around the electric grid. These features help prevent accidental contact by humans or larger animals, minimizing the risk of electric shock.

Do Insectocutors require regular maintenance?

Answer: Yes, Insecto-cutors require regular maintenance to ensure optimal performance. This includes cleaning the electric grid and collection tray, replacing adhesive boards or glue traps, and periodically checking the UV light bulbs.

Can Insectocutors be used in food processing areas?

Answer: Yes, certain Insecto-cutors are suitable for use in food processing areas. However, it is essential to choose models specifically designed for such environments and comply with any food safety regulations in place.

Are there energy-efficient options available for Insectocutors?

Answer: Yes, there are energy-efficient Insecto-cutors available in the market. These models are designed to consume lower power while maintaining effective insect control, resulting in energy savings and reduced environmental impact.

Can Insectocutors eliminate all types of flying insects?

Answer: Insecto-cutors are primarily effective against flying insects that are attracted to light, such as mosquitoes, flies, and moths. However, they may be less effective against insects that are not attracted to UV light or crawling pests that do not fly. Other methods may be required to control these types of pests effectively.