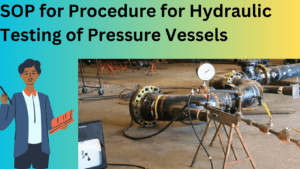

The purpose of this (Standard Operating Procedure) SOP for Procedure for Hydraulic Testing of Pressure Vessels is to outline the steps and guidelines for conducting hydraulic testing of pressure vessels to ensure their structural integrity and compliance with safety standards.

SOP for Procedure for Hydraulic Testing of Pressure Vessels

- OBJECTIVE:

- To lay down the Procedure for safely and effectively conducting of hydro testing for pressure vessels.

- SCOPE:

- This SOP is applicable for hydro testing of installed vessels in Utility/process area.

- RESPONSIBILITY:

- Technician/ Operator/ EHS/ Engineering shall be responsible for proper execution of testing operation as per SOP.

- EHS – Head shall be responsible for reviewing the SOP and for ensuring proper execution.

- ACCOUNTABILITY:

- Engineering – Head shall be accountable for proper implementation of the SOP.

- DEFINITIONS:

- Program manager:

- Project manager or maintenance manager who is responsible for all mechanical activities happening at site.

- Custodian:

- The person who is responsible for using the equipments for plant production purpose.

SOP for Procedure for Hydraulic Testing of Pressure Vessels

- PROCEDURE:

- Hydrotest planning:

- Determines test pressure after consulting the project engineer/engineering department head. Note: when hydrostatic testing is performed on an existing pressure system, the original hydrostatic test pressure must not be exceeded.

- Complete the pressure test plan and submits for approval.

- Hydro test shall be carried out by third party person as when required.

- Performing Hydrotest:

- Ensures that the pressure gauges used for hydro test should be calibrated & calibration expiry date is within limit.

- Removes all persons which are not involved in the test from the testing area.

- Removes pressure relief valves or non-reclosing relief device from the vessel or test boundary where the test pressure will exceed from the set pressure of the valve or Holds down each valve by means of an appropriate test clamp and pressurizes both sides of non-reclosing relief devices or Installs temporary, higher-rated devices which is applicable.

- Installs the calibrated test gauge.

- Ensures the skillet blanks or test plugs or clamps are appropriate for use and are free of obvious defects.

- Remove the air of vessel through vent as much as possible.

- Ensures that the temperature of water used for the test should be ambient temperature.

- Pressurizes the system, raising the pressure in the system gradually until the designated test pressure is equal to 1.3 times of the MAWP achieved.

- Maintain this test pressure for 10 minutes before inspection. Then, if test is above maximum allowable working pressure (MAWP), reduces to MAWP while making a full thorough inspection for leaks.

- Ensures the metal temperature at the time of the hydrostatic test should not exceed 49°C.

- If there is evidence of structural distortion, either rejects the system or repairs as advised by inspector.

- If there is leakage in the system, performs the following as appropriate:

- Ensure repairs are performed and returns to step 6.2.8 or Reject the system.

- When the test is completed, vents the test pressure to atmosphere and return the relief valves to normal configuration.

- Record the hydro test result as per Format No. SOP/EN/XXXYYY in case of inhouse test.

- Completes pressure test record and submits copy to the pressure system program manager.

- Submits copies of the test plan and test record to the EHS and Custodian.

- ABBREVIATIONS

- CRF No. : Change Request Form number

- QA : Quality Assurance

- MAWP : Maximum Allowable Working Pressure

- MWP : Maximum Working Pressure

- EHS : Environment Health And Safety.

- REFERENCES

- Nil.

- DISTRIBUTION LIST

- SOP shall be distributed to following departments Quality Assurance, Engineering as per user request

- ANNEXURES

- Record of hydro test of pressure vessel: SOP/EN/XXXYYY

SOP for Procedure for Hydraulic Testing of Pressure Vessels

RECORD OF HYDRO TEST OF PRESSURE VESSEL

| Date | Equipment ID | Test start | Test Stop | Pressure Hold Time | Observation | Tested By | Ensured By | Reviewed By | Remark |

Hi Sir,

Please send the SOP to chethan.n@vmarsbio.com