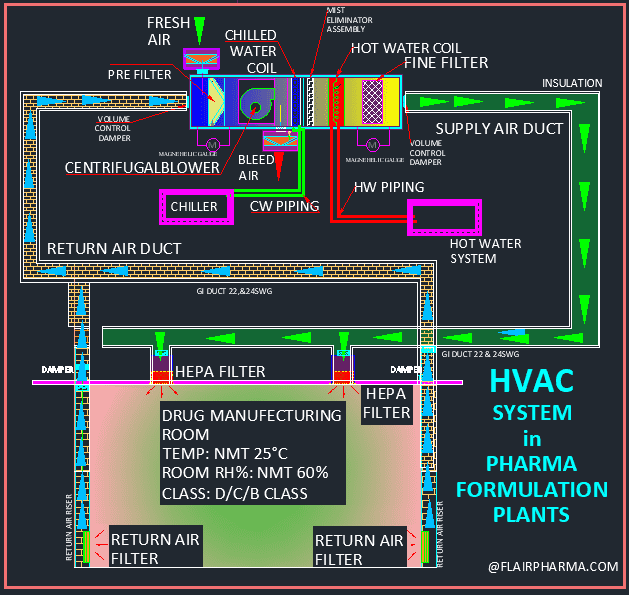

In a pharma HVAC interview, you can expect questions that assess your technical knowledge of HVAC systems, including their design, operation, and maintenance. You may be asked about various types of HVAC equipment, such as chillers, boilers, air handlers, and exhaust systems, as well as their components and functions.

GMP Compliance: Good Manufacturing Practices (GMP) are critical in the pharmaceutical industry to ensure product quality and safety. Interviewers may ask about your understanding of GMP requirements and how they apply to HVAC systems in a pharma setting. You may be asked about clean room classifications, air changes per hour (ACPH), temperature and humidity control, and monitoring systems.

#1. What does HVAC stand for?

#2. Which of the following is NOT a function of HVAC in pharmaceutical plants?

#3. What is the purpose of air filtration in HVAC systems in pharmaceutical plants?

#4. What is the recommended temperature range for most pharmaceutical manufacturing areas?

#5. What type of air handling unit (AHU) is commonly used in pharmaceutical plants to provide conditioned air to production areas?

#6. What is the purpose of a cleanroom in a pharmaceutical plant?

#7. What is the acceptable range of relative humidity (RH) in pharmaceutical cleanrooms?

#8. What is the purpose of a laminar flow hood in a pharmaceutical cleanroom?

#9. Which of the following is NOT a method of air disinfection commonly used in pharmaceutical cleanrooms?

#10. What is the purpose of a pressure cascade in pharmaceutical cleanrooms?

#11. What is the purpose of an exhaust system in a pharmaceutical plant?

#12. Which of the following is NOT a common source of air contamination in pharmaceutical plants?

#13. What is the recommended air change rate (ACPH) for an ISO Class 5 cleanroom?

#14. What is the purpose of a desiccant dehumidifier in an HVAC system?

#15. Which of the following is NOT a factor that affects the performance of HVAC systems in pharmaceutical plants?

#16. What does ISO 14644 refer to in the context of HVAC systems?

#17. ISO 14644 classifies cleanrooms based on which of the following parameters?

#18. Which of the following is NOT a requirement of ISO 14644 for cleanroom HVAC systems?

#19. ISO 14644 classifies particulate matter in cleanrooms based on their size range in micrometers. What is the maximum allowable limit for Class 5 cleanrooms?

#20. ISO 14644 recommends that HVAC systems in cleanrooms should be designed to achieve which of the following goals?

#21. According to ISO 14644, what is the recommended frequency for testing and monitoring of cleanroom HVAC systems?

#22. ISO 14644 requires that cleanroom HVAC systems should be qualified and validated. What does this mean?

#23. ISO 14644 recommends that HVAC systems in cleanrooms should be equipped with alarms or other indicators to alert when which of the following conditions are not met?

#24. Which of the following ISO standards is related to the classification of air cleanliness in cleanrooms?

HVAC Interview Question

HVAC Interview Question