Metal detection features are commonly used in tablet manufacturing machines to ensure that the final product is free from any metal contamination. Metal contaminants can come from a variety of sources such as raw materials, machine parts, or the manufacturing environment, and can pose a serious health risk to consumers.

Processes of Metal Detection

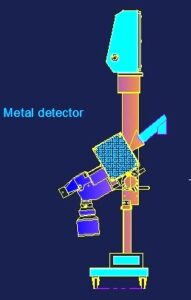

- Metal detectors: These are devices that use electromagnetic induction to detect the presence of metal objects. Metal detectors can be placed at various points in the tablet manufacturing process to detect metal contaminants in raw materials, tablet components, or finished products.

- Automatic rejection systems: When a metal contaminant is detected, the automatic rejection system is activated, which automatically removes the contaminated tablet from the production line. This ensures that only non-contaminated products reach the consumers.

- Sensitivity settings: Metal detectors can be adjusted to different sensitivity levels, depending on the type and size of metal contaminants that need to be detected. This ensures that even the smallest metal contaminants are detected and removed from the production line.

- Data recording: Modern tablet manufacturing machines are equipped with data recording features that track the performance of the metal detection system. This helps manufacturers to identify potential issues and make necessary adjustments to prevent metal contamination.

Working Principle Metal detectors

Metal detectors used in tablet manufacturing plants work on the principle of electromagnetic induction. The basic principle of electromagnetic induction is that when an electrical current flows through a coil of wire, it creates a magnetic field around it. When a metal object is brought near the coil, it disrupts the magnetic field, causing an electrical signal to be generated in the coil. This signal is then processed and used to detect the presence of metal.

In a tablet manufacturing plant, MDs are typically integrated into the production line. Tablets are passed through an MD as they move along a conveyor belt, gravity-fed chute, or pipeline. As each tablet passes through the MD, it is scanned by a coil of wire that creates a magnetic field around it. If the tablet contains any metal, it will disrupt the magnetic field, causing an electrical signal to be generated in the coil. This signal is then processed by the MD’s control unit, which can determine the location and size of the metal object.

When a metal object is detected, the metal detectr’s automatic rejection system is activated, which removes the contaminated tablet from the production line. In some cases, the metal detectr may be set to a lower sensitivity level, allowing for smaller metal objects to pass through without triggering the rejection system. This is often done when detecting smaller metal objects is not critical to the manufacturing process or when it is not feasible to remove every single contaminated tablet.

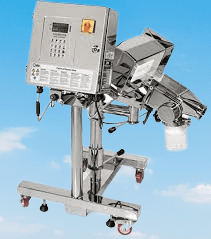

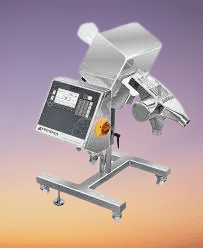

Types of metal detectors in the tablet manufacturing plant.

There are several types of metal detectrs that are commonly used in tablet manufacturing plants, including:

- Conveyor metal detectors: These are designed to detect metal contaminants in tablets moving along a conveyor belt. They are commonly used in high-volume production environments and can be customized to fit specific conveyor systems.

- Gravity-fed metal detectors: These are designed to detect metal contaminants in tablets as they fall through a gravity-fed chute. They are commonly used in applications where tablets are produced in large batches.

- Pipeline metal detectors: These are designed to detect metal contaminants in liquids or semi-solids as they pass through a pipeline. They are commonly used in tablet manufacturing plants for detecting metal contaminants in liquids used in tablet production.

- Handheld metal detectors: These are portable metal detectrs that can be used to quickly and easily scan tablets for metal contaminants. They are commonly used during the inspection process to ensure that tablets are free from metal contamination.

- X-ray metal detectors: These use X-ray technology to detect metal contaminants in tablets. They can also detect other contaminants, such as glass or stone, commonly used in pharmaceutical manufacturing plants.

Metal detector circuit working

A metal detectr circuit works by using electromagnetic induction to detect the presence of metal objects. The basic components of a metal detectr circuit include a coil of wire, an oscillator, a signal amplifier, and a detection circuit.

When the oscillator is activated, it sends a high-frequency signal to the coil of wire. The coil then creates a magnetic field around it, which extends beyond the coil’s physical boundaries. If a metal object is placed near the coil, it will disrupt the magnetic field, causing a change in the oscillator’s frequency. This change in frequency is detected by the signal amplifier, which amplifies the signal and sends it to the detection circuit.

The detection circuit then analyzes the amplified signal to determine if the change in frequency is due to the presence of metal. If metal is detected, the detection circuit activates an alarm or other indicator to alert the user of the metal’s presence.

The sensitivity of the metal detectr circuit can be adjusted by changing the oscillator’s frequency or by varying the number of turns in the coil of wire. Higher frequencies and more coil turns to increase the sensitivity of the metal detectr circuit, allowing it to detect smaller metal objects or those that are farther away from the coil.

Different sensors are used in the metal detector.

There are several types of sensors that can be used in metal detectrs, each with its own advantages and disadvantages. Here are some of the most common types of sensors used in metal detectrs:

- Induction balance sensors – these sensors work by measuring changes in the magnetic field caused by the presence of metal objects.

- Pulse induction sensors – these sensors use short bursts of electricity to generate a magnetic field and detect changes in the field caused by metal objects.

- Very low-frequency sensors – these sensors use a low-frequency electromagnetic field to detect metal objects.

- Beat frequency oscillation sensors – these sensors work by comparing the frequency of a reference oscillator with that of an oscillator affected by the presence of metal objects.

- Microwave sensors – these sensors use high-frequency electromagnetic waves to detect metal objects.

- Hall-effect sensors – these sensors work by measuring changes in the voltage caused by the presence of a magnetic field generated by a metal object.

The choice of sensor used in a metal detectr depends on several factors, including the type of metal to be detected, the desired sensitivity of the metal detectr, and the environment in which the metal detectr will be used.

Metal detector price in India:

The price of metal detectors in India can vary depending on various factors such as the type of metal detectr, the brand, the features, and the sensitivity. Generally, the price range of metal detectrs in India can vary from around INR 5,000 to INR 1,00,000 or even more for high-end models.

Some of the popular metal detectr brands available in India include Garrett, Minelab, Whites, Fisher, and Nokta Makro. The price of metal detectrs from these brands can range from INR 5,000 to INR 70,000 for entry-level to mid-range models. High-end models with advanced features can cost over INR 1,00,000.

It is important to consider your budget and requirements before purchasing a metal detectr. You may also want to read reviews and compare different models to find the best metal detectr that fits your needs and budget.

Frequently Asked Questions:

What is the purpose of metal detectors in a tablet manufacturing plant?

Answer: The purpose of metal detectrs is to detect metal contaminants in tablets to ensure that the final product is free from any metal contamination.

What types of metal detectors are commonly used in tablet manufacturing plants?

Answer: Commonly used metal detectrs in tablet manufacturing plants include conveyor metal detectrs, gravity-fed metal detectrs, pipeline metal detectrs, handheld metal detectrs, and X-ray metal detectrs.

How do metal detectors work in tablet manufacturing plants?

Answer: Metal detectrs work on the principle of electromagnetic induction. As tablets pass through a metal detectr, a coil of wire creates a magnetic field around it. If the tablet contains any metal, it will disrupt the magnetic field, causing an electrical signal to be generated in the coil. This signal is then processed by the metal detector’s control unit.

What happens when a metal object is detected in a tablet manufacturing plant?

Answer: When a metal object is detected, the metal detectr’s automatic rejection system is activated, which removes the contaminated tablet from the production line.

Can metal detectors detect other types of contaminants besides metal?

Answer: Some metal detectrs, such as X-ray metal detectrs, can detect other types of contaminants besides metal, such as glass or stone.

Where are metal detectors typically located in a tablet manufacturing plant?

Answer:: Metal detectrs are typically integrated into the production line and can be located at various points, such as at the beginning of the production line, in the packaging area, or in the quality control area.

How are metal detectors calibrated in a tablet manufacturing plant?

Answer:: Metal detectrs are calibrated by using test pieces of known sizes and compositions to verify their sensitivity and accuracy.

Can metal detectors be customized to fit specific tablet manufacturing processes?

Answer:: Yes, metal detectrs can be customized to fit specific tablet manufacturing processes, including conveyor systems, gravity-fed chutes, and pipelines.

What are the benefits of using metal detectors in a tablet manufacturing plant?

Answer: The benefits of using metal detectrs include ensuring that the final product is free from metal contamination, reducing the risk of harm to consumers, and maintaining compliance with industry regulations.

Are metal detectors required by law in tablet manufacturing plants?

Answer: Regulations may vary by country, but in many cases, metal detectors are required by law in tablet manufacturing plants to ensure the safety and quality of the final product.

You may also read about the History of Microbiology.