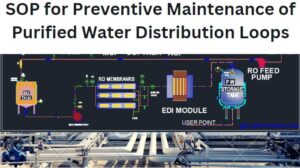

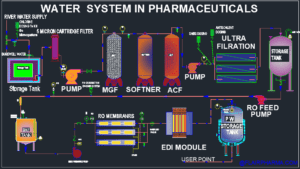

The SOP for Preventive Maintenance of Purified Water Distribution Loops is to establish a comprehensive procedure for conducting preventive maintenance on the purified water distribution loops in order to ensure their reliable operation, maintain water quality, and prevent potential contamination risks.

SOP for Preventive Maintenance of Purified Water Distribution Loops

- OBJECTIVE:

- This SOP is describing the Preventive Maintenance of Purified Water Distribution Loops

- SCOPE:

- This SOP is applicable for the preventive Maintenance of Purified Water Distribution Loops installed in final treatment installed at plant .

- RESPONSIBILITY:

- Technician/ Operator shall be responsible for proper execution of preventive maintenance as per SOP of Preventive Maintenance of Purified Water Distribution Loops.

- Engineering – Head shall be responsible for reviewing the SOP and for ensuring proper execution of preventive maintenance of Purified Water Distribution Loops.

- ACCOUNTABILITY:

- Engineering – Head shall be accountable for proper implementation of the SOP for Preventive Maintenance of Purified Water Distribution Loops.

- DEFINITIONS:

- A detailed document that outlines step-by-step instructions and guidelines for performing specific tasks or processes consistently and safely within an organization. Water that has undergone purification processes to remove impurities, contaminants, and particles, meeting specific quality standards for use in critical applications of the Preventive Maintenance of Purified Water Distribution Loops.

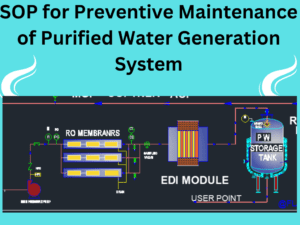

- PROCEDURE:

- Preventive maintenance shall be executed as per the SOP No.: SOP/EN/XXXYYY – Execution of Preventive Maintenance of Purified Water Distribution Loops.

- Ensure that the spare parts are available at the time of preventive maintenance.

Preventive Maintenance of Purified Water Distribution Loops – Mechanical

- Checking of pipeline and fittings

- Physically check all the pipe line supports and clamps and tighten them if found loose.

- Physically check the tri-clover clamps on pipeline and fittings for leakages. If any leakage is present then physically check the silicon gaskets, if found damaged (cut, deform, leached, shape changed) replace the same and tighten the clamp.

- Checking shall be done six monthly.

- Checking of Diaphragm Valve

- Check the valve for smoothly movements, if the operating hand wheel of valve is found jammed or stuck, then open the valve and carry out the maintenance as follows.

- Switch of the pump.

- Close the nearby upside and down side valves.

- Open the TC ends, loose the diaphragm valves nut by the Allen key, check the valve for damaged diaphragm, clean the valves, and check for the locking nut of diaphragm.

- If gasket found damaged (cut, leached, deform, shape and size change) change the diaphragm.

- After physically checking of diaphragm valve, refit in to the system and check for leakage and valve operation if found satisfactorily then it is okay otherwise replace the valve.

- For actuated diaphragm valve check for the performance of actuator for valve opening and closing as per interlocks of the system

- Checking of valve shall be done monthly.

- Checking of Back pressure regulating valve

- Check the back pressure regulating valve for the end connections if required tight the same.

- Check the working of Back Pressure regulating valve after every month

- Checking of pumps

- Physically check the pump for any abnormal noise if found, Disconnect the pump motor wiring.

- Disconnect the pump from the pipeline and open the pump.

- Physically check the condition of bearings, mechanical seal, shaft, impeller and replace if found damaged.

- Checking of the pumps shall be done quarterly.

Checking of instruments in Preventive Maintenance of Purified Water Distribution Loops – Mechanical

- Ensure that the installed instruments are calibrated.

- Checking of instruments shall be done monthly for its proper functioning.

- Physically check the instruments end connection, if required tight the contacts. The following instruments are installed in distribution loop.

- Temperature transmitter installed on top nozzle of tank

- Compound pressure gauge installed on top nozzle of tank.

- Capacitance type level transmitter installed on top nozzle of tank.

- Conductivity transmitter installed in suction line of pump.

- Temperature transmitter on installed on return line of distribution loop.

- Flow transmitter installed on return line of distribution loop.

- Pressure gauge installed on discharge line of pump.

- Siphon type pressure gauge installed on plant steam line.

- Checking of UV lamp

- Check and ensure that the UV lamp burning hours from hour meter and it should not exceed the recommended burning hours.

- Check the intensity of the UV lamp; if required replaces the UV lamp.

- The replacement of UV lamp shall be accordingly to the SOP No.: SOP/EN/XXXYYY

- Checking of filter housing

- Check the micron filter housing for any dents; leakages; internal finishes.

- Check the filter locking nut threading.

- Checking of frequency shall be quarterly.

- Checking of tank and accessories

- Visually inspect the tank internally for surface roughness, crashes, cleanliness, damage, dent and rusting; if found clean thoroughly and rectify the same.

- Physically check and inspect the tank insulation and cladding, if required repair.

- Physically check the end connection to tank for leakages, if required rectifies the same.

- Physically check the tank installed instruments such as level transmitter, compound pressure gauge for proper functioning, if required remove, clean and refit the same or if necessary replace the same.

- Check the functioning of spray ball operation.

- After carrying out the preventive maintenance of tank, pump and distribution piping sanitization cycle should conduct and verify the sanitization procedure as per SOP No. SOP/EN/XXXYYY

- Checking of tank shall be done after every six month.

- Checking of vent filter

- Physically check the vent filter housing for the roughness, crashes, cleanliness, damaged, dent and rusting, if found clean thoroughly and rectify the same.

- The vent filter replacement is carried out as per SOP/EN/XXXYYY.

- Checking of printer

- Check the printer for paper alignment and printer cartridge ribbon.

- Checking of printer frequency shall be done after every six month.

- Checking of Spare Parts

- Check the stock for following spare parts.

- Checking frequency shall be after very six month.

| Sr. No. | Spare Part Descriptions | Specification | Quantity (Nos.) |

| Spray Ball | ¾ “ NB | 1 | |

| Float type level switch | 1 | ||

| Compound Pressure Gauge | -1 to 9 bar | 1 | |

| Vent Filter Cartridge | 0.2 µ ; 5 “ Long | 1 | |

| Vent Filter Housing | 5” Long | 1 | |

| Distribution Pump | 2 m3/hr / 55 MWC | 1 | |

| UV Sterilizer | 2 m3/hr | 1 | |

| Pressure Gauge | 0 to 10 Kg/cm2 | 1 | |

| Temperature Sensor | 0 to 150 deg C | 1 | |

| Temperature Transmitter | 0 to 150 deg C | 1 | |

| Conductivity sensor and transmitter | 0 – 10 µs/cm | 1 | |

| Manual Diaphragm Valve | ¾” OD | 1 | |

| Sr. No. | Spare Part Descriptions | Specification | Quantity (Nos.) |

| Manual Diaphragm Valve | 2” OD | 1 | |

| Manual Diaphragm Valve | 1” OD | 1 | |

| Manual zero dead leg valve | 1” OD | 8 |

- Checking of tank (PW distribution) and pipelines for any rouging.

- Check the tank (PW distribution) and pipelines for any rouging.If found, clean the surface of PW distribution tank and pipelines with buffing or electro polishing process.

- Checking shall be done after every six month

- Challenge test for dumping valve.

- Change the set value of conductivity parameter in HMI system and put the set value less than the Current value.

- Once the process value becomes higher than the set value, dump valve shall open automatically and dumping of PW shall start. Record the changed value and functioning of dumping valve in preventive maintenance record Format Number.: SOP/EN/XXXYYY.

- Sanitization shall be carried out after testing of valve.

- Change the conductivity value in HMI as per original value.

- Checking shall be done monthly.

Preventive Maintenance of Purified Water Distribution Loops – Electrical

- Checking of terminals and wiring

- Ensure that the power supply to the panel is switched off.

- Visually check all the power and control wiring and terminals in the electric control panel and at field instruments.

- Check and ensure by using screwdriver that all the wires are properly tightened.

- Checking shall be done six monthly.

- Checking of contactors

- Switch off the main switch on the electrical panel.

- Disconnect all the control and power wires from the contactor terminals.

- Remove dust from control panel with help of air blower.

- Remove the contactor from the panel and visually check all the contacts for pitting and carbon deposits on the contacts.

- Clean all the contacts with carbon tetra chloride or with contactor cleaner. Replace the contacts if found damaged or welded.

- Put back the contactor in the panel and connect all the wires to the original locations.

- Check the earthing of the panel body.

- A good earthing shall show less than 2 Volts between the Neutral Wire of the Incoming Power supply and Panel Body.

- Checking of contactors shall be done six monthly.

- Checking of induction motor of centrifugal type distribution pump

- Check the insulation resistance of motor winding with the help of megger.

- Check the phase continuity and winding continuity of motor with the help of tong tester.

- Physically check the motor terminal box and terminal connections.

- Check the voltage drawn by motor with the help of multimeter

- Check the current drawn by motor with the help of tong tester.

- Physically check the direction of rotation; it should be as per recommended direction.

- Checking shall be done after every six month.

- Checking of VFD terminals

- Switch off the main switch on the electrical panel.

- Check all the contacts and clean with carbon tetra chloride or with contactor cleaner.

- Checking of VFD contacts shall be done six monthly.

- Checking of PLC

- Check the PLC for blinking of LED.

- Check the display

- Check the wiring contacts, if required tight the same.

- Checking of PLC shall be done after every six month.

Post Preventive Maintenance of Purified Water Distribution Loops – Check List

- Record the Preventive Maintenance details as per the Format No.: SOP/EN/XXXYYY “Preventive Maintenance Checklist & Record for Purified Water Distribution Loops”.

- Whenever any modifications and major works are carried out to the equipment, the same shall be mentioned in the equipment history card as per the respective SOP.

- Connect the equipment main power supply and start the equipment.

- Ensure that the equipment is running smoothly, without any abnormality.

- If any abnormality is observed in the above, same will be attended in co-ordination with User department Head.

- ABBREVIATIONS:

- CRF No. : Change Request Form number

- QA : Quality Assurance

- PLC : Programmable Logical Controller

- LED : Light Emitting Diode

- VFD : Variable Frequency Drive

- SOP : Standard operating procedure.

- TC : Tri clover

- REFERENCES:

- Nil

- DISTRIBUTION LIST:

- SOP shall be distributed to following departments Quality Assurance, Engineering as per user request.

- ANNEXURES:

- Preventive maintenance checklist and record for Purified Water Distribution Loop:- SOP/EN/XXXYYY

Checklist & Records for the Preventive Maintenance of Purified Water Distribution Loops

PM CHECKLIST & RECORD

| Equipment Name | Location | ||

| Equipment ID | Frequency |

| Things to be done: | Check List | ||||

| Monthly Check List | |||||

| Checking of valves for their proper functioning | |||||

| Checking of instruments for its proper functioning. | |||||

| Challenge test for dumping valve AF1VT1 1301 | |||||

| Current conductivity value (µs/cm) | Changed conductivity Value (µs/cm) | Function of Dumping valve | |||

| Quarterly Check List in Preventive Maintenance of Purified Water Distribution Loops | |||||

| Checking of pump for abnormal sound; damage of bearings, mechanical seal; shaft; impeller. | |||||

| Checking of vent filter | |||||

| Checking of spray ball proper functioning. | |||||

| Half Yearly Check List in Preventive Maintenance of Purified Water Distribution Loops | |||||

| Checking of pipe line and pipe fittings for leakages; pipe support; if required tighten them if found loose. | |||||

| Checking of instruments for end connection tightness; if required tight the contacts. | |||||

| Ensure that the installed instruments are calibrated. | |||||

| Checking of the UV lamp intensity with intensity meter; if required replace the UV lamp. | |||||

| Checking of filter housing for any dents; leakages; internal finishes. | |||||

| Checking of tank and tank accessories. | |||||

| Checking of printer for paper alignment and printer cartridge ribbon. | |||||

| Checking of contactors. | |||||

| Checking of terminals and wiring. | |||||

| Checking of VFD for contacts. | |||||

| Checking of electrical motor. | |||||

| Checking of PLC for display; blinking of LED and wiring contacts. | |||||

| Check the tank (PW distribution) and pipelines for any rouging.If found, clean the surface of PW distribution tank and pipelines with buffing or electro polishing process. | |||||

| Yearly Check List in Preventive Maintenance of Purified Water Distribution Loops | |||||

| Check the burning hours of the UV lamp; if it is exceeds than the recommending hours; then replace the UV lamp. | |||||

good info