Friability testing with a Friability Tester is a crucial procedure in pharmaceutical laboratories to assess the mechanical strength of tablets. It evaluates the tendency of a tablet to chip, break, or powder during handling, packaging, and shipping. The friability tester, plays a vital role in ensuring that tablets meet the necessary quality standards before they reach the market. This article explores the various uses, operational procedures, and maintenance of friability testers in laboratory settings.

The Purpose of Friability Testing:

Friability testing is essential for several reasons:

- Quality Control: Ensures tablets can withstand mechanical stresses without degrading.

- Compliance: Meets regulatory requirements set by pharmacopeias such as the United States Pharmacopeia (USP).

- Product Stability: Assesses the long-term stability of the tablet form.

- Formulation Development: Helps in optimizing tablet formulations to achieve the desired mechanical properties.

Components and Configurations:

The Friability Tester comes in two main configurations: single-drum and dual-drum models. The dual-drum configuration allows for simultaneous testing of two different samples, enhancing efficiency in the laboratory. The tester operates by rotating the drum at a constant speed of 25 RPM, simulating the mechanical stresses tablets might encounter during production and transportation.

Operating the Friability Tester without a Printer

- Setup: Ensure the tester is properly connected and the drum is clean.

- Loading: Place the required number of tablets (usually 10) into the drum.

- Starting the Test: Disable the PRINT key if not using a printer. Set the test duration or number of rotations.

- Weighing: Weigh the tablets before and after the test to calculate the percentage of weight loss.

With a Printer

- Printer Setup: Connect the printer to the tester and ensure it is online.

- Running the Test: Load the tablets, set the duration, and start the test. The printer will document the start time, operating mode, and set duration.

- Weighing and Recording: After the test, enter the ending weights into the tester. The printer will automatically calculate and print the percentage of weight loss.

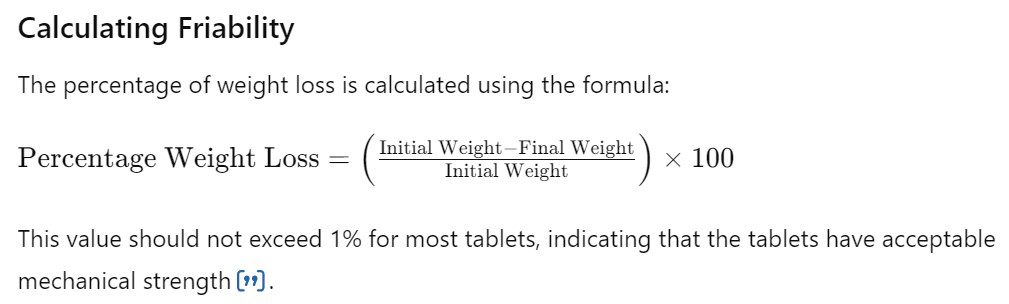

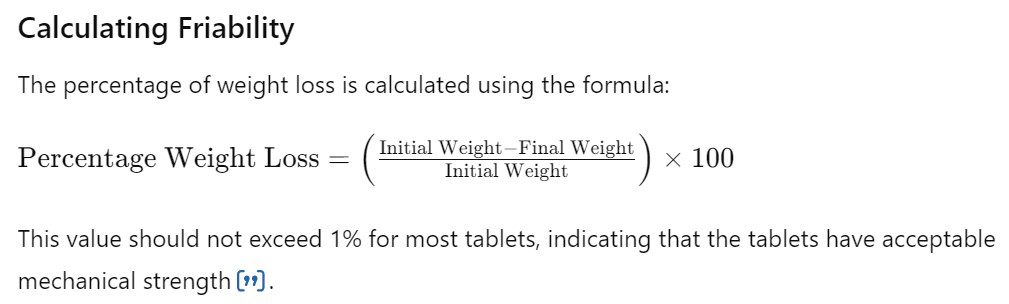

Calculating Friability:

The percentage of weight loss is calculated using the formula:

This value should not exceed 1% for most tablets, indicating that the tablets have acceptable mechanical strength.

Working Principle of the Friability Tester:

A friability tester is an essential instrument in pharmaceutical laboratories, used to measure the durability of tablets when subjected to mechanical stress. The primary goal is to assess the tablets’ resistance to abrasion, which is crucial for ensuring they can withstand handling, packaging, and transportation without breaking or crumbling.

Principle of Operation:

The working principle of a friability tester involves simulating the mechanical stresses that tablets might encounter during various stages of their lifecycle. Here’s a detailed breakdown of how the device operates:

- Preparation of Tablets:

- Sample Selection: Typically, a sample of 10 tablets is selected for the test. For larger tablets, fewer may be used, provided the total weight is around 6.5 grams.

- Initial Weighing: The selected tablets are accurately weighed to determine their initial mass.

- Loading the Tablets:

- The weighed tablets are placed into the drum of the friability tester. The drum is usually made of transparent material, allowing the operator to observe the test.

- Setting the Parameters:

- Rotation Speed: The standard rotation speed is set to 25 revolutions per minute (RPM).

- Test Duration: The drum is typically set to rotate for a specific number of revolutions (usually 100) or for a specific time period (typically 4 minutes).

- Rotational Motion:

- Drum Rotation: The drum begins to rotate at the set speed. Inside the drum, baffles lift the tablets and allow them to fall freely as the drum rotates. This action simulates the mechanical stress of handling and transportation.

- Impact and Abrasion: As the tablets tumble inside the rotating drum, they collide with each other and with the drum’s walls. This repeated impact and abrasion process mimics the physical stresses that tablets endure in real-world scenarios.

- Completion of the Test:

- After the set number of rotations or time period, the drum stops rotating. The tablets are then carefully removed from the drum.

- Final Weighing:

- The tablets are dusted off to remove any loose particles that may have formed during the test.

- The tablets are then reweighed to determine their final mass.

- Calculation of Friability:

- Weight Loss Calculation: The percentage of weight loss is calculated using the formula.

- This percentage represents the friability of the tablets. A weight loss of less than 1% is typically considered acceptable for most tablets.

Importance of the Test:

The friability test is crucial for ensuring the mechanical integrity of tablets. It helps in:

- Quality Control: Ensuring that tablets can withstand handling without significant breakage.

- Regulatory Compliance: Meeting pharmacopeial standards such as those set by the United States Pharmacopeia (USP).

- Product Development: Optimizing tablet formulations to achieve the desired mechanical properties.

Technical Specifications of the Friability Tester:

| Specification | Details |

| Model | Standard Friability Tester |

| Configurations | Single-drum and Dual-drum |

| Drum Material | Transparent acrylic or polycarbonate |

| Drum Diameter | 287 mm (11.3 inches) |

| Drum Depth | 38 mm (1.5 inches) |

| Number of Drums | 1 (Single-drum) / 2 (Dual-drum) |

| Rotation Speed | 25 RPM |

| Rotation Count | Up to 100 rotations (default) |

| Test Duration | Typically 4 minutes |

| Tablet Capacity | 10 tablets (standard) |

| Total Sample Weight | Approximately 6.5 grams |

| Power Supply | 110-240V AC, 50/60 Hz |

| Power Consumption | 50 W |

| Display | Digital LCD display |

| Weight Measurement | Analytical balance (external) |

| Dimensions (W x H x D) | 400 mm x 350 mm x 300 mm |

| Weight | Approximately 15 kg |

| Compliance | USP, EP, BP guidelines |

| Control Interface | Keypad or touch screen (model-specific) |

| Printer Connectivity | Yes (for models with printer support) |

| Calibration | Automatic or manual |

| Operating Temperature | 15°C to 30°C (59°F to 86°F) |

| Storage Temperature | 0°C to 50°C (32°F to 122°F) |

| Humidity Range | 20% to 80% RH (non-condensing) |

| Safety Features | Overload protection, emergency stop |

| Certification | CE, ISO 9001 |

Maintenance of the Friability Tester:

Regular maintenance ensures the accuracy and longevity of the friability tester. The Friability Tester requires:

- Daily Cleaning: Wipe down the exterior with a clean cloth and plain water. Avoid using abrasive cleaners, especially on the acrylic drums.

- Monthly Checks: Inspect the drums for cracks, clean the shaft, and ensure the pins are not bent.

- Annual Maintenance: Check electrical connections for corrosion, clean both the interior and exterior, and ensure proper belt tension.

Safety Considerations:

Operating the friability tester involves handling electrical components. It is essential to follow safety protocols to prevent electric shocks and other hazards:

- Qualified Personnel: Only trained personnel should operate and maintain the tester.

- Protective Equipment: Use appropriate personal protective equipment (PPE) during operation.

- Regular Inspections: Conduct regular safety inspections to identify and mitigate potential risks.

Types of Friability Testers:

Friability testers come in various types, each designed to meet specific needs and testing requirements in pharmaceutical laboratories. Below are the primary types of friability testers:

Single-Drum Friability Tester

Description:

- This type features a single rotating drum where the tablets are placed for testing.

Key Features:

- Suitable for routine testing of tablet batches.

- Compact design, ideal for smaller laboratories.

- Typically used for straightforward, standard friability tests.

Applications:

- Quality control for small to medium production batches.

- Ideal for research and development phases.

Dual-Drum Friability Tester:

Description:

- Equipped with two rotating drums, allowing simultaneous testing of two samples.

Key Features:

- Increased efficiency by testing multiple samples at once.

- Independent control of each drum for different test parameters.

- Saves time in high-throughput environments.

Applications:

- Large-scale production quality control.

- Laboratories requiring high-throughput testing.

Programmable Friability Tester

Description:

- Features advanced programming capabilities for customized test protocols.

Key Features:

- User-friendly interface with programmable test methods.

- Ability to store and recall multiple testing protocols.

- Advanced data logging and connectivity options.

Applications:

- Detailed research and development applications.

- Laboratories needing precise control over testing parameters.

Portable Friability Tester

Description:

- Designed for mobility and ease of use in various locations.

Key Features:

- Lightweight and compact design.

- Battery-operated options for field testing.

- Easy to transport between different lab locations or manufacturing sites.

Applications:

- On-site testing in manufacturing facilities.

- Research labs with space constraints.

Heavy-Duty Friability Tester

Description:

- Built for testing large tablets or batches with higher mechanical stress requirements.

Key Features:

- Robust construction for handling high-stress testing.

- Larger drums and higher capacity for bigger tablets.

- Enhanced durability for continuous use.

Applications:

- Large-scale manufacturing environments.

- Testing tablets that require higher mechanical strength validation.

Automated Friability Tester

Description:

- Fully automated systems for high-efficiency, unattended operation.

Key Features:

- Automatic loading and unloading of tablets.

- Integrated weighing and data processing.

- Minimal human intervention required.

Applications:

- High-throughput production facilities.

- Laboratories focusing on reducing manual labor and increasing efficiency.

Specialized Friability Testers

Description:

- Customized testers designed for specific types of tablets or unique testing requirements.

Key Features:

- Tailored to meet specific regulatory or product-specific needs.

- May include features like humidity control or advanced data analysis tools.

- Designed for specialized applications or unique tablet formulations.

Applications:

- Testing tablets with unique shapes or formulations.

- Compliance with specific regulatory requirements for niche markets.

Applications in Pharmaceutical Laboratories:

Formulation Development:

In the initial stages of drug development, friability testing helps in formulating tablets that meet desired mechanical properties. By adjusting the composition and processing parameters, formulators can create tablets that are both effective and durable.

Quality Control:

Before tablets are released to the market, they undergo rigorous quality control tests, including friability testing. This ensures that only tablets with acceptable mechanical strength are distributed, reducing the risk of product recalls due to tablet breakage or powdering.

Stability Testing:

Friability testing is also used in stability studies to assess how the mechanical strength of tablets changes over time under various environmental conditions. This information is crucial for determining the shelf life of the product.

You May also read about:

- Karl Fischer Titrator of QC Lab

- hplc principle and working in QC

- Lab Desiccators in the pharmaceutical Plant

Frequently Asked Questions (FAQ’s)

What is the use of a friability tester?

Answer: A friability tester is used in pharmaceutical laboratories to determine the friability of tablets, which is their tendency to crumble or break under mechanical stress. This test simulates the stresses tablets may encounter during manufacturing, packaging, and transportation to ensure they are durable enough to reach consumers intact. The friability tester helps in quality control and formulation development by ensuring that the tablets can withstand these stresses without significant degradation.

What is friability a measure of?

Answer: Friability measures the mechanical strength of tablets, specifically their ability to resist abrasion, chipping, and breakage. It quantifies the extent to which tablets can endure handling and transportation without losing significant mass or becoming too fragile.

When should the friability test be performed?

Answer: The friability test should be performed during various stages of tablet development and production:

- Formulation Development: To optimize the tablet formulation for mechanical strength.

- Quality Control: To ensure that each batch meets the required mechanical strength standards before release.

- Stability Testing: To evaluate how the mechanical strength of tablets changes over time under different storage conditions.

What is the principle of friability?

Answer: The principle of friability involves rotating tablets in a drum with baffles that lift and drop the tablets repeatedly, simulating the mechanical stresses experienced during handling. The tablets are weighed before and after the test, and the percentage of weight loss is calculated. This weight loss indicates the friability of the tablets.

What is the unit of friability?

Answer: Friability is expressed as a percentage (%), representing the weight loss of the tablets due to abrasion and mechanical stress.

What if the friability test fails?

Answer: If the friability test fails (i.e., the percentage weight loss exceeds the acceptable limit), the tablets may be too fragile for handling and transportation. Actions to take include:

- Reformulating the Tablet: Adjusting the composition or processing conditions to improve mechanical strength.

- Reevaluating the Manufacturing Process: Identifying and mitigating factors that may contribute to tablet fragility, such as inadequate compression force or excessive moisture.

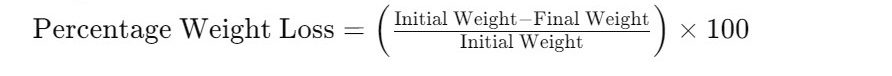

How to calculate friability?

Answer:

What affects friability?

Answer: Several factors can affect the friability of tablets:

- Tablet Composition: The ingredients and their proportions can impact mechanical strength.

- Compression Force: The force used during tablet compression affects density and friability.

- Moisture Content: High moisture levels can weaken tablets, increasing friability.

- Granule Size and Shape: The size and shape of the granules used in tablet formulation can influence mechanical properties.

- Storage Conditions: Environmental factors like temperature and humidity during storage can affect tablet friability.

What is the rpm of friability?

Answer: The drum of a friability tester typically rotates at a constant speed of 25 revolutions per minute (RPM).

What is the reason for friability failure?

Answer: Friability failure can result from several issues, including:

- Inadequate Compression: Insufficient compression force during tablet formation.

- Poor Formulation: Ineffective binding agents or inappropriate proportions of excipients.

- Excessive Moisture: Tablets absorbing too much moisture, leading to weakened structure.

- Improper Storage: Exposure to adverse environmental conditions during storage.

- Manufacturing Defects: Issues in the manufacturing process leading to inconsistent tablet quality.

What is the acceptable range of friability?

Answer: The acceptable range of friability for most tablets is typically less than 1%. However, specific requirements may vary depending on the tablet type and regulatory guidelines.

How is friability measured?

Answer: Friability is measured by subjecting tablets to mechanical stress in a rotating drum, weighing them before and after the test, and calculating the percentage of weight loss. This process is standardized to ensure consistency and reliability of results.

What is the sample size for friability testing?

Answer: The sample size for friability testing usually consists of 10 tablets. If the tablets are larger and heavier, fewer may be used, but the total weight should be around 6.5 grams.

What is the unit of tablet hardness?

Answer: Tablet hardness, also known as tablet crushing strength, is typically measured in kiloponds (kp) or Newtons (N).

How to use a friability tester?

Answer: To use a friability tester:

- Preparation: Ensure the tester is clean and properly set up.

- Loading: Place the required number of tablets into the drum.

- Running the Test: Set the rotation speed (usually 25 RPM) and duration (usually 4 minutes or 100 rotations).

- Weighing: Weigh the tablets before and after the test.

- Calculating: Calculate the percentage weight loss to determine friability.

What is the purpose of the friability test?

Answer: The purpose of the friability test is to assess the mechanical durability of tablets to ensure they can withstand the physical stresses of manufacturing, packaging, and transportation without significant degradation.

What is a friability machine called?

Answer: A friability machine is commonly referred to as a friabilator or friability tester.

What to do if a friability test fails?

Answer: If a friability test fails:

- Investigate the Cause: Identify potential reasons for failure, such as formulation issues or manufacturing defects.

- Adjust the Formulation: Modify the tablet composition to improve mechanical strength.

- Improve Manufacturing Processes: Ensure optimal compression force, proper drying, and handling procedures.

What is the height of the friability tester?

Answer: The height of a friability tester can vary based on the model and manufacturer. Specific dimensions should be referenced from the user manual of the device.

What is meant by friability?

Answer: Friability refers to the tendency of tablets to crumble, break, or lose weight due to abrasion or mechanical stress during handling, packaging, and transportation.

What is friability calculation?

Answer: Friability calculation determines the percentage weight loss of tablets subjected to mechanical stress using the formula:

What is the rpm of the friability tester?

Answer: The standard rotational speed of the friability tester drum is 25 RPM.

How do you solve friability problems?

Answer: To solve friability problems:

- Reformulate: Adjust the tablet formulation to improve binding and strength.

- Optimize Compression: Increase the compression force during tablet formation.

- Control Moisture: Ensure tablets are adequately dried and stored in controlled environments.

- Quality Control: Implement stricter quality control measures during manufacturing.

How many tablets are used in a friability test?

Answer: Typically, 10 tablets are used in a friability test. For larger tablets, the total weight tested should be around 6.5 grams.

What is the speed of friability?

Answer: The speed of the friability tester drum is typically set at 25 revolutions per minute (RPM).

What is the sample size of friability test?

Answer: The sample size for a friability test generally consists of 10 tablets, or a total weight of around 6.5 grams for larger tablets.

Supplier List of Friability Testers

Below is a list of reputable suppliers that provide friability testers. These suppliers offer a range of friability testers to meet different laboratory needs, from basic models to advanced programmable and automated systems.

1. Agilent Technologies

Description: Agilent Technologies is a well-known supplier of pharmaceutical testing equipment, including high-quality friability testers.

- Website: Agilent Technologies

- Products: Single-drum, dual-drum, and programmable friability testers.

- Support: Comprehensive customer support and service options.

2. Sotax

Description: Sotax specializes in providing solutions for pharmaceutical testing, including robust and reliable friability testers.

- Website: Sotax

- Products: Single-drum and dual-drum friability testers, automated systems.

- Support: Extensive global service network and technical support.

3. Erweka

Description: Erweka is a global manufacturer of pharmaceutical testing equipment known for its innovative and high-quality products.

- Website: Erweka

- Products: Basic to advanced friability testers, including automated models.

- Support: Worldwide service centers and technical assistance.

4. Pharma Test

Description: Pharma Test offers a wide range of testing equipment for the pharmaceutical industry, including friability testers.

- Website: Pharma Test

- Products: Basic, dual-drum, and automated friability testers.

- Support: Detailed technical support and training services.

5. Electrolab

Description: Electrolab provides innovative and reliable pharmaceutical testing instruments, including a variety of friability testers.

- Website: Electrolab

- Products: Single-drum, dual-drum, and programmable friability testers.

- Support: Comprehensive support and calibration services.

6. Labindia Analytical Instruments

Description: Labindia offers a broad range of analytical instruments for pharmaceutical testing, including durable and precise friability testers.

- Website: Labindia Analytical Instruments

- Products: Basic and advanced friability testers.

- Support: Technical support and maintenance services.

7. Copley Scientific

Description: Copley Scientific specializes in pharmaceutical testing equipment and offers a variety of friability testers to suit different requirements.

- Website: Copley Scientific

- Products: Single-drum, dual-drum, and automated friability testers.

- Support: Expert support and comprehensive training.

8. Distek, Inc.

Description: Distek is a leading provider of pharmaceutical testing equipment, including advanced friability testers designed for high precision.

- Website: Distek, Inc.

- Products: Programmable and automated friability testers.

- Support: Excellent customer support and technical assistance.

9. Buchi

Description: Buchi offers a range of laboratory equipment, including high-quality friability testers designed for reliability and ease of use.

- Website: Buchi

- Products: Basic to advanced friability testers.

- Support: Global support network and technical services.

10. ACG Group

Description: ACG Group provides a wide range of pharmaceutical testing equipment, including efficient and accurate friability testers.

- Website: ACG Group

- Products: Single-drum, dual-drum, and automated friability testers.

- Support: Comprehensive service and support options.

Hey people!!!!!

Good mood and good luck to everyone!!!!!