Quality Control in the pharmaceutical industry has a crucial role in the quality slandered of Pharma products. The main goal of quality control is to evaluate and compare product quality to predefined criteria. Quality control is therefore the most important aspect of the pharmaceutical industry. The process of quality control also includes finding any product flaws and using corrective methods and procedures to address them. It is the procedure of checking and approving goods to make sure they adhere to regulatory and customer standards. In a pharmaceutical setting, quality management includes quality control as a crucial component. In Pharma Industry 4. O the Quality control department plays a very crucial role.

The goal of quality control in the pharmaceutical industry

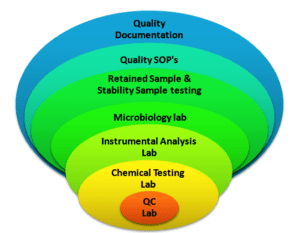

The primary goal of quality control in the pharmaceutical industry is to test the medications at different stages of production to ensure that they can move on to the next stage and are produced in line with the rules and standards necessary for human use. They must be tested in several work areas to have full control over the quality of the medication being produced. The primary subjects of study and analysis are:

- Laboratory for physical-chemical testing.

- In-Process Control Laboratory.

- Microbiology Laboratory

- Laboratory for packaging materials.

- Packing Material Testing Laboratory.

There are various rules that are essential for the proper manufacture and monitoring of pharmaceutical quality. Every nation has its own set of laws and regulations that these procedures must abide by in order for an industry to produce goods. There are internal and external audits aimed at inspecting good manufacturing procedures for medicines to make sure that the regulations and legislation are being applied correctly.

According to each drug’s requirements and the stage it is in, analyses are carried out. The simplest to the most complex controls are carried out in the physical-chemical laboratory. We can list the product’s appearance, hardness, density, and pH as simple analyses. The most popular technique employed today in the largest pharmaceutical enterprises in the world, the content of the product (dosage), performed in a device called HPLC, is more complicated (High-Performance Liquid Chromatography).

Bestsellers in water dispensers & more

Bestsellers in water dispensers & more

Steps of quality control in the pharmaceutical industry

Each product has a production process, which includes raw materials, an initial product, a finished product, and a stability study. Each product then undergoes a physicochemical analysis in a lab that is affecting quality control in the pharmaceutical industry.

- Raw material (RM) testing work: Any substance utilized in the creation of medication, whether active or not, regardless of origin, whether it remains intact during the process or undergoes changes or disappears, is referred to as a raw material. Hence, excipients and active ingredients are considered raw materials.

- Mid-Level (Intermediate) Product testing work: The partially processed mixture of the raw material with the required inputs in their proper amounts, known as an intermediate product, must go through additional production procedures before becoming a bulk product.

- Drug Bulk or FG product testing Wok: Any product that has been through all the steps of a medicine’s production before the packaging procedure is concluded is referred to as a bulk product or finished product. Bulk products are sterile goods that are still in their original packaging.

- Stability sample testing work: A stability study involves periodically checking on each drug or pharmaceutical ingredient to make sure it retains or doesn’t lose a significant amount of its effectiveness. As with the other product phases, it is also conducted in a lab. The results can show how these compounds may change over time as a result of environmental influences including temperature, light, and humidity.

Tasks that are handled by quality control in the pharmaceutical industry:

- Raw materials, IPQC samples, packaging materials, and finished products are sampled and analyzed.

- Preparation, and approval of documentation containing the testing records and analysis of samples.

- Specifications and test procedures for raw materials, in-process samples, finished products, and packaging materials are prepared and reviewed.

- QC – SOP preparation and review.

- examination of QC error.

- calibrations of the QC lab’s equipment and machinery.

- stability evaluation of the products that are kept in stability chambers.

- GLP assurance in the laboratory.

- Product arrival, processing, and final inspection.

- Equipment internal calibration.

- control of the lab’s equipment.

- control over samples.

- keeping track of calibration and inspection records.

- The specification and standard testing procedures should be reviewed and approved.

- Check out and sign the calibration record.

- The working standard qualification record should be reviewed and approved.

- Examination of raw materials, packaging materials, in-progress products, and finished goods in accordance with specifications and accepted test methods.

- Analyze and give your approval for the volumetric solution preparation and standardization record.

- Raw data analysis and reports for unfinished, in-progress, semi-completed, and finished goods.

- Specifications for raw materials, packaging materials, in-process products, and finished goods (STP, GTP, and TDS).

- All systems in the quality control lab are validated as per the validation protocol.

These all above checks are the major point in quality control in the pharmaceutical industry.

Why Is Quality Control Important in the Pharmaceutical Industry?

Drug quality is important since it affects human health and well-being. Poor quality control procedures can have disastrous effects when dealing with consumable goods that people depend on. Quality control in the pharmaceutical industry ensures the following things:

- To assure patient safety—clearly, this is the pharmaceutical industry’s top priority. Prior to receiving approval for use, all pharmaceuticals must adhere to a set of safety requirements, and it is the responsibility of quality control to ensure that these requirements are met.

- To adhere to regulations; one of the most strictly regulated sectors in the world is the pharmaceutical industry. Quality control is crucial to guaranteeing compliance with all laws, both in the nation where the pharmaceuticals are manufactured and in the nations where they will be sold.

- To preserve the company’s reputation; in a field where consumer confidence is so crucial, a company’s reputation can be readily damaged by even a single quality control error. For this reason, pharmaceutical businesses go to tremendous pains to guarantee that their goods adhere to the highest standards.

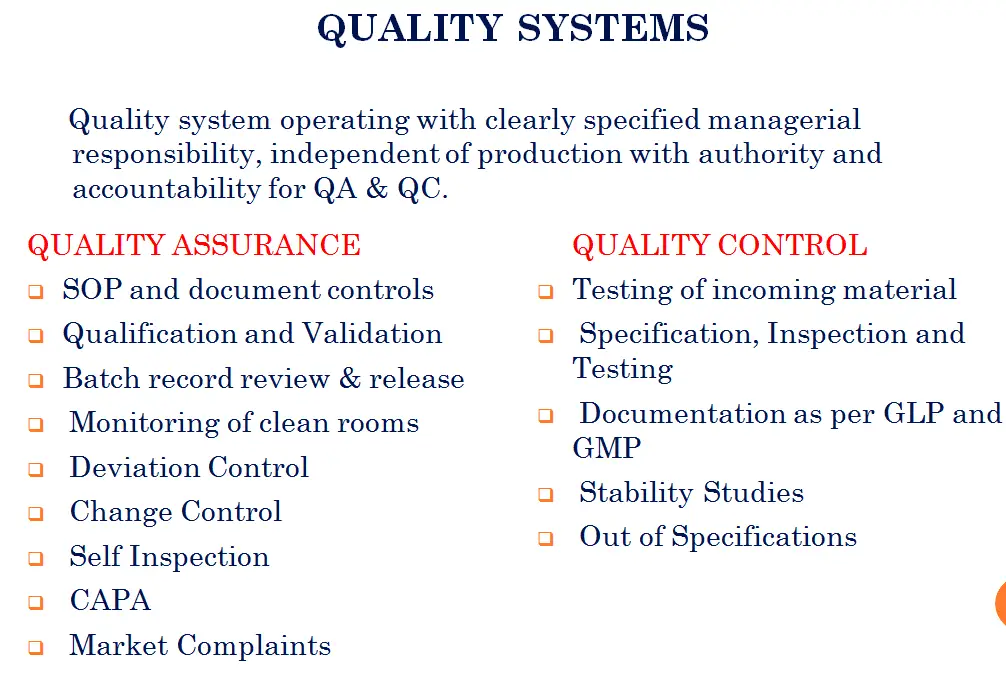

What is the difference between QA and QC?

quality control in the pharmaceutical industry:

What Are the Steps of Quality Control in the Pharmaceutical Industry?

quality control in the pharmaceutical industry is crucial. Let’s look at the processes that are normally included in the process.

- Testing the raw materials that will be utilized to create the medicine is the first step in the quality control process. This is crucial to make sure the materials are of the required caliber and to confirm that they haven’t been polluted in any manner. quality control in pharmaceuticals plays an important role.

- In-process testing: Following approval, raw materials are delivered to the factory floor to be converted into the finished product. At various phases of production, in-process testing is done to make sure the medicine satisfies all quality requirements.

- Testing the finished product to ensure that it satisfies all requirements is the third and last step in quality control. Only goods that pass this last round of testing are made available for purchase. quality control in the pharmaceutical industry has a direct impact on the product.

You may also check out for Microbiology Guidelines.

Good job 👍

QC Chemical/Physical Testing is an essential part of the pharmaceutical manufacturing process. By rigorously testing the chemical and physical properties of products, pharmaceutical companies can ensure that their products are safe, effective, and of the highest quality.

Quality control in pharmaceutical industry is the backbone , ensuring that every product meets the highest standards of safety and efficacy. It’s impressive to see how advanced technologies and stringent regulations are continually improving the quality control processes. This not only boosts consumer confidence but also minimizes risks associated with drug manufacturing. How do you see the role of AI and automation evolving in quality control within the pharmaceutical sector?”